STUTTGART, Germany—Bosch is focused on the future at its most historic plant.

Nikola trucks in the U.S. will be the first to receive Bosch fuel-cell power modules, which have begun volume production here at the company’s Stuttgart-Feuerbach plant, it announced during a U.S. press tour of the company’s oldest facility.

Bosch leaders said their hydrogen technology will help the trucking industry—in major global economic markets—meet decarbonization goals faster than relying on battery-electric technology. With fueling times similar to diesel—and much quicker than recharging batteries—hydrogen has the potential to fit more easily into U.S. trucking long-haul applications, Thomas Wintrich, Bosch’s head of Fuel Cell Mobility Solutions, said during a House of Journalists press briefing.

Hydrogen and fuel-cell adoption and success in the trucking industry will come down to total cost of ownership, Wintrich said at the Feuerbach site, which has 15,000 employees and first opened in 1910.

“The driver is always TCO in the trucking industry,” he said. “If you have the infrastructure and you can create TCO, which it seems Nikola can do for the trucks, then it becomes interesting.”

Creating hydrogen fueling infrastructure and fuel costs comparable to diesel, which might need government support, would help trucking leaders see the TCO opportunities for hydrogen fuel cells and internal combustion engines, Wintrich explained.

Initial Bosch fuel-cell customers in Europe and China have been able to get “in the region of 800 kilometers (497 miles) running time” per fueling, he said. “That seems to be something which is really helpful for long-distance trucking. And for sure, the short fueling time is an advantage nowadays, and it will be an even bigger advantage when you think about automated driving because you don’t have the pauses for the driver anymore.”

Bosch betting on fuel cells over BEV trucks

Compared to battery-electric trucks, which must sacrifice several tons of cargo payload for large batteries and long recharging times, hydrogen fuel cells and engines potentially offer similar refueling times and range to diesel-powered trucks. “That is exactly where we need the breakthrough to show that the maturity level—even with this completely new process, this completely new supply chain—really works,” Wintrich said. “We now have a chance to connect experiences with our first customers. It’s not only with Nikola but also in China, which is already running around. We have already collected nearly 3 million kilometers (1.86 million miles) on our trucks in China.”

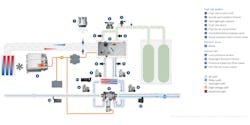

By 2030, Bosch expects to generate 5 billion euros ($5.36 billion) through hydrogen technology developed within its global manufacturing network. The Bosch plant in Bamberg, Germany, will supply the Feuerbach factory with the fuel-cell stack. System components, such as the electric air compressor and recirculation blower, are built in Homburg.

Along with production that has begun in Europe and China, Bosch plans to manufacture fuel-cell stacks for trucking applications at its plant in Anderson, South Carolina. Bosch executives said one in five new heavy-duty trucks worldwide will run on fuel-cell powertrains by 2030.

Between 2021 and 2026, Bosch will invest nearly 2.5 billion euros ($2.68 billion) in developing and manufacturing hydrogen technologies, more than the supplier initially planned to invest in 2021.

Hydrogen-based mobility and stability

In advocating for a hydrogen economy, the company has argued that hydrogen is the only way the world can achieve climate neutrality.

Earlier this year, Bosch began constructing electrolysis prototypes using proton exchange membranes to produce hydrogen to power mobile and stationary fuel cells. Starting this fall, Bosch announced it will begin making 1.25-megawatt prototypes for pilot applications; volume production is planned for 2025.

The company is exploring several options for hydrogen use. Stationary solid-oxide fuel cells can be used for distributed power and heat supplies, company representatives explained during the plant tour on Sept. 8. It is starting a micro-powerplant pilot project at a hospital near Cologne, Germany, that will initially run on natural gas before being converted to green hydrogen.