Tesla delivered its first production electric Semi trucks to PepsiCo, the second largest private fleet in the U.S., at the Tesla Gigafactory in Nevada on Dec. 1—five years after CEO Elon Musk first unveiled the Tesla Semi prototype.

"There's been a lot that's happened since then, to say the least," Musk said during the event that featured PepsiCo- and Frito-Lay-branded Semi day cabs on stage. "We're incredibly excited tonight to actually deliver our first production Tesla Semi Trucks."

PepsiCo is No. 2 on the FleetOwner 500: Private Fleets list. The private fleet delivered a load of Frito-Lay snacks to the launch event, where PepsiCo's North America chief executive Steven Williams was handed a key card to one of the Semis. It was not clear how many trucks the company procured on Dec. 1.

See also: Musk touts Tesla Semi's range days before first fleet gets EV truck

"It looks sick," Musk said from a stage, flanked by four Semis. "You want to drive that. I mean, that thing looks like it came from the future."

PepsiCo said on its website that as the company "continuously explores emerging technologies that will position us for the future, we made an initial reservation for 100 all-electric Class 8 tractors from Tesla. These will be deployed across both our snacks and beverage businesses." Additionally, Pepsi said its Frito-Lay division would deploy more than 40 electric vans in North America in 2022 to evaluate how best to leverage electric vehicles and technologies moving forward.

According to Tesla, the Class 8 Semi's range per charge is between 300 and 500 miles when loaded to 82,000 lbs. GVWR (battery-electric and natural gas trucks are granted an extra ton by the Federal Highway Administration). The OEM also lists the Semi's energy consumption as "less than 2 kWh/mile." Due to its sleek contours, the Semi also will be less affected by drag at highway speeds, with a drag coefficient of 0.36, or about half of a conventional diesel Class 8's wind resistance, according to Tesla.

The Tesla Semi was initially slated for 2019 production, but the timeline has been pushed back multiple times. In 2020, Musk claimed that all engineering work on the Semi had been completed and that Tesla expected to begin deliveries in 2021. The availability of battery cells was the only issue limiting the vehicle's production, Musk said at the time. Months later, Tesla didn't provide much of a progress report except to say the Semi was in development.

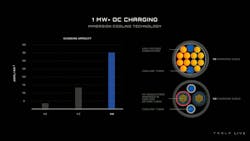

Musk said the battery-electric tractor was built using a 1,000-volt architecture that would allow it to use a liquid-cooled megawatt charger that is about three times more powerful than current systems. He said it could recharge the battery to 70% in a half-hour. He also said that the planned Cybertruck pickup would be compatible with the system.

Dan Priestley, Tesla truck engineering senior manager, told the crowd gathered in Nevada on Dec. 1 that the Semi has been tested in the "hot, cold, snow, and rain" weather testing. He added that Tesla would use the Semi within its fleet. Over the weekend, Musk posted on Twitter that the Semi completed a 500-mile trip with a nearly fully-loaded trailer from Fremont, California, to San Diego.

"We've been putting this thing through its paces in the lab as well as the real world," Priestley said. "The simulation team has been doing an incredible job of being able to scale all of that on the virtual side. And the other thing is that we're going to take these—we're going to put our money where our mouth is—and we're going to put these into our own fleet, into our own supply chain. And we're going to use this to transport goods between our factories and our suppliers because we believe in it not just from a mission perspective and a cost perspective but because we want to close that feedback loop."

He said Tesla would rely on driver and technician feedback as it refines the Semi. In California, where electricity is 2.5 times less costly than diesel, Tesla estimates an operator would save $200,000 in fuel costs over the first three years of ownership of the electric Class 8.