Navistar ramps up EV fleet consulting, unveils new infrastructure partnership

ANAHEIM, California—City of Industry, California-based US Air Conditioning Distributors, which runs a fleet of 28 trucks and tractors for HVAC distribution services, isn’t new to the alternative-power landscape.

The HVAC distributor’s fleet began its decarbonization journey 15 years ago with compressed natural gas (CNG) after the company realized that in California vehicles operating on an alternative fuel could drive in the HOV lane with a single driver. That made CNG an efficiency win for the fleet.

“We started out the journey back then, wanting to get our products out to our customers faster,” Jack Scarsi, VP of operations and finance at US Air Conditioning Distributors, told FleetOwner at this year’s Advanced Clean Transportation Expo. “At that point in time, our option was CNG. We looked at the cost of the fuel, and it was less than diesel. Now, 15 years later CNG is not considered clean burning anymore in California.”

As the company began to phase out its CNG fleet, Scarsi went to the fleet’s International Trucks dealer, Westrux International, and began its battery-electric journey with Navistar’s International eMV Series trucks.

“About a year and a half ago, I worked with Anthony [the fleet’s Westrux International representative] who told me what grants were available,” Scarsi said. “It was an easy process to work with him, they had all the paperwork filled out, and within a month, I had access to fund seven electric 24-ft. flatbed trucks.”Before committing to all seven, however, Scarsi opted to take delivery of two trucks so the company’s drivers could test drive the electric trucks. The fleet also worked with Navistar on installing DC fast charging on-site.

“Our drivers were completely blown away by the pickup, the power, and the silence of driving these trucks,” Scarsi said. “They are a completely different experience than driving a diesel.”

The advertised range for an eMV battery-electric is about 135 miles, but Scarsi said his fleet has been able to achieve a 160-mile range on one charge due to the weight of the cargo they haul. It also doesn't hurt to train drivers on regenerative braking.

“The regenerative braking is something new for them, and we had to explain the benefits of regenerative braking,” Scarsi noted. “You’re going to save on your range, you’re going to add to the range when you use your regenerative brakes, you’re going to save wear and tear on the actual brakes, and in some cases, it’s actually less physically stressful on your foot because you just let off and the truck brakes. The comfort of driving an electric truck versus a diesel is night and day.”

Scarsi’s goal now is to continue working with his International dealer’s team to electrify 100% of US Air Conditioning Distributors’ fleet.

Quanta infrastructure venture: How fleets can benefit

For fleets, part of getting the most from EVs is understanding duty cycles, power options, and route optimization. That’s where Trish Reed, VP of zero emissions for Navistar, and her team come in.

Working with US Air Conditioning Distributors, Reed told FleetOwner that the Navistar team in California analyzed the fleet’s routes to ensure that they were optimal for electrification. Navistar’s team also took lessons learned from the OEM’s IC Bus operation, which supplies both electric and conventional ICE school buses to school districts across the U.S.

“Sometimes you have a school that has a board that wants to buy 40 electric school buses, but when you go in and look at their routes and make sure they have the right routes that could accommodate the school buses, it might just be 20 routes today based on range, stops, starts, and ambient temperatures,” Reed explained. “You’ve got a lot of different inputs to that.”

“And then on the truck side, you have various weights when you get into different applications,” Reed added. “The great thing has been these learnings from school bus and medium-duty, and then as we go into our regional haul, it’s going to get even better.”During ACT Expo, Navistar announced its newly formed partnership with integrated infrastructure solutions partner Quanta Services. Quanta provides engineering, construction, and maintenance services, as well as power and infrastructure assessment for EV charging and related infrastructure in the North American market.

“Our electric vehicles are only as strong as the grid that powers them,” said Mathias Carlbaum, president and CEO of Navistar. “The differentiator of this partnership is Quanta’s ability to complete site construction and utility work. This allows our team to offer the customer a one-stop-shop approach to all aspects of an EV transition.”The partnership with Quanta capitalizes on Navistar’s three-step approach to delivering fully integrated eMobility solutions to customers: consulting, charging, and deployment.

Navistar’s EV consulting process begins with establishing an EV roadmap for customers by hosting discovery workshops designed to understand fleet needs and concerns around electrification. Reed added that the Quanta partnership will help customers partner directly with utilities to assist in power requirement analyses and sourcing responsible energy.

Navistar also works to determine hardware and charging depot locations for each individual fleet. When EVs are ready to be deployed, Navistar’s OnCommand Connection technology allows for advanced remote diagnostics and the ability to turn vehicle health data into actionable insights.

“We’re not just going in and selling a vehicle,” Reed noted. “We are going in and assessing the situation, asking questions, doing the range analysis and the route optimization to say, ‘Here’s what we think is the best path to take.’ But part of that, too, is looking at the long term. We have customers that have sustainability goals, so you’ve got to look at the short term and how that blends into the longer-term planning.”

Million-mile milestone for EVs, new ePTO options

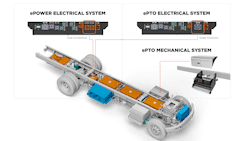

Another major announcement for Navistar during ACT Expo is that the International eMV Series now has factory-installed ePower and electric power takeoff (ePTO) electrical system options available.

“Last month, our International Truck and IC Bus electric vehicles passed a major milestone: logging 1 million miles driven. This equates to a reduction of carbon emissions by more than 800 metric tons,” said Göran Nyberg, EVP of commercial operations at Navistar.

See also: Navistar delivers its first all-electric straight truck with ePower

During a press conference at the show, Carlbaum reiterated the OEM’s vision of accelerating the impact of sustainable mobility.

“We remain dedicated to reaching 50% zero-emission vehicles by 2030, charging capacity allowing it,” Carlbaum said. “We are doing that step by step, segment by segment, application by application, and customer by customer. TCO parity will happen within most segments in this timeframe. At that point, nothing will hold this industry back. Like most OEMs, we strive to go beyond where the regulators aim.”

Since launching the International eMV Series at ACT Expo in 2021, Carlbaum said the company has experienced an exponential increase in fleets looking to electrify. And as Navistar continues on its path toward scaling EVs, Carlbaum emphasized the importance of well-to-wheel sustainability as well.

“Zero-emission vehicles is not enough,” he said. “Our source of energy must be transitioned in sustainable options. At International, the target is not to be the first nor to be the largest. It’s all about having the best value proposition, making our customers prosper, and being the preferred option.”

That means ongoing collaboration with dealer networks and industry partners to demonstrate various applications for fleet customers.

“In less than two years, we have partnered with customers to expand the original box truck application of the eMV Series into electric bucket trucks, mini mixers, stake dumps, utility vehicles, and more,” said Debbie Shust, VP of Navistar’s medium-duty truck business. “Now, we are proud to provide ePower and electric power take-off options for customers that utilize the vehicle’s battery to provide power to other parts of the vehicle.”

ePower and ePTO availability, gearing up for Class 8 BEVs

With the availability of the ePower and ePTO electrical system options, fleets can now spec International eMV Series Classes 6 and 7 battery-electric trucks for additional market applications. Additionally, the OEM has laid the foundation for the introduction of a Class 8 battery-electric vehicle.The ePower electrical system option pulls power directly from the EV's battery pack and is the foundation for electric transport refrigeration unit (eTRU) applications.

“We worked in close collaboration with transport refrigeration unit providers and leading food transport service fleets, including Performance Food Group (PFG), to develop and bring this solution to market,” said Shust.

In addition to working with PFG on ePower, Navistar and PFG are focused on a long-term zero-emission future. Chet Ciesielski, VP of Navistar’s on-highway business, noted the OEM “is committed to supporting customers for all use cases, including the development of a Class 8 battery-electric vehicle.”

The ePTO electrical system option pulls power directly from the vehicle's battery and utilizes an electric motor to convert power for other systems on the truck, such as a boom or concrete mixer. Electric utility and telecommunications equipment provider Altec has taken delivery of the first eMV Series truck with a factory-installed ePTO electrical system to operate a pilot distribution bucket truck.

Preparing dealers, fleet customers for the EV paradigm shift

At the end of the day, Navistar is intent on working with its partners to ensure dealers and fleets have their infrastructure and charging in place when EVs arrive.

Navistar, as well as its competitors across the industry, are urging fleets that want to electrify to start the charging infrastructure process sooner than later.

See also: Start your alt-fuel training efforts today

“This step can be complex and depending on the complexity and the scope of the project, it can take 18 to 24 months to complete, if not longer,” Reed advised. “If there is one piece of advice I can give everyone, it’s start today.”

That’s because the biggest paradigm shift, according to Reed, is that it’s no longer just about the trucks. Now, OEMs and their fleet and dealer customers must also consider charger maintenance.

And Navistar has been stepping up to manage charger uptime as well, Reed pointed out. That means setting up call centers and being able to remotely diagnose charging stations that run into issues.

“My advice is to put in a charging station as soon as you can,” US Air Conditioning Distributors’ Scarsi also noted. “Most fleet owners will have employees with electric vehicles already. It’s not a bad thing to have ready to go and then when you get your trucks you can plan bigger but get something you can use to charge those trucks overnight.”