After a heated freight market fueled elevated rates and expensive equipment procurement, the cooling economy coupled with a more productive supply chain could help the trucking industry weather economic uncertainty ahead. And that means fleets could finally procure more trucks and trailers in 2023.

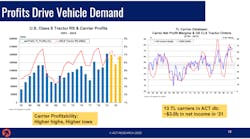

“When truckers make money, they’re going to buy trucks,” noted Tim Denoyer, ACT Research VP and senior analyst, during the firm’s Seminar 67 in Columbus, Indiana, on Aug. 25. He cited the historical relationship between operating margins and Class 8 tractor retail sales.

“It’s at peak levels this year—even in this tough environment,” he told a crowd of transportation executives gathered for ACT’s twice-yearly seminar. “There’s enough marginal momentum coming into this year that we think margins overall are going to be flat this year—even though they’re going to be down in the second half and down next year.”

See also: ‘Who cares’ if this is a recession? CV demand could prop up market

He noted that the industry had its best financial year in 2021. Despite downturns this half of 2022, Denoyer said this could be the “third or fourth best year from a carrier profitability standpoint.”

The equipment supply shortages that began this decade and drove up prices are starting to ease, Denoyer said: “That’s pulling some of those extraordinary prices back to Earth.”

Class 8 market rebound vs. recession fears

"The economic activity generates the freight, the freight generates the profits that the carriers make—and it's those profits that drive equipment demand," explained Kenny Vieth, ACT Research president and senior analyst.

Vieth said that despite some economic headwinds facing North America and the trucking industry, ACT is expecting a "shallower downturn than we typically see" in the Class 8 vehicle market.

The constrained supply the industry faced since the COVID-19 pandemic began nearly 30 months ago could help it weather a recession into 2023. "At the top of the list was no carrier overbuy," Vieth said. "Because of supply chain constraint, truckers could not get the industry to build as many trucks as they would have liked to have bought."

See more: July Class 8 orders down sharply

The orders for those trucks were coming in by the end of 2020 as the industry saw the freight demand rising, but "the supply chain laid an egg," Vieth explained. "That's important because we did not have that extra 100,000 or extra 80,000 products entering the market over the course of '21 and '22. So we come to the downturn with a relatively lean new vehicle profile in the market."

The supply chain constraints also kept truck dealers from overbuying. This lean inventory will keep equipment demands high through 2023, Veith said. "There are significant known-unknowns that make this a very challenging market to forecast," he added. "What happens with European recessions? What nefarious plans does Vladimir Putin have? Or Xi Jinping for that matter? And what is the Fed going to do?"

Vieth described several powerful good and bad forces at work that are already affecting the commercial vehicle equipment industry. On the bad side is inflation, rising interest rates, the end of the COVID-19 consumer binge, trucking spot rates falling, and lingering supply chain constraints. On the positive side, North American economic demand is "hanging on," strong consumer and business balance sheets, low unemployment, strong job market, industrial economic momentum, and pent-up manufacturing demand.

"We still don't have a lot of 2023 orders in the books as the OEMs are being very judicious in opening those order books—whether it's trying to figure out what the truck is even going to cost, but also trying to manage expectations," he said. "Because the last couple of years, there have been a lot of trucks ordered that didn't get built."

While Class 8 order backlogs are down about 56,000 year-over-year, there is still a large backlog, Vieth said. But the "everything shortage" is easing as build rates are finding some traction. "Inventories are in balance as retail sales are largely tracking production right now," he added.

According to ACT Research, the backlog-to-build ratio stands at eight months, while the inventory-to-retail-sales ratio is around 2.3 months. And Veith added that Class 8 order cancellations by fleets is nearly nonexistent.

According to OEM data shared with ACT, truckmakers plan to build 81,000 Class 8s in the third quarter of 2022, 77,000 in Q4, and 81,000 in Q1 2023. But there are an extra 28,000 orders in the Q3 backlog and another 20,000 in Q4. Vieth said there's been a "consistent overhang of orders that aren't getting built in the backlog," leading to that eight-month waiting period for fleets.

Fleet demand for trailers isn't slowing down

"Carriers are making money and they're buying trucks—and they're also buying trailers because it takes something to put the goods in or on to make this whole process work," said Jennifer McNealy, ACT's director of commercial vehicle market research and publications. "Demand is strong and supply constraints are easing. Labor remains challenging for some more than others, depending on their geography."

Trailer OEMs have begun to take some orders for 2023. "They've cracked the door a little bit for the trailer market—but it's certainly not swung wide open and backlogs are well into 2023," she explained.

See also: Keeping trailers properly utilized

In July, ACT Research pinned the trailer backlog at 185,225. During the same month, just more than 23,000 trailers were built while inventory stood around 27,000. The OEMs took more than 18,000 new orders in July, saw nearly 1,300 cancelations, and shipped just over 22,000 units.

McNealy noted that the trailer order backlog fell 3% in July compared to June. But year-to-date, trailer backlogs are up 1%. Trailer builds fell 13% month-over-month but are 3% higher than a year ago. Trailer inventor was up 4% in July compared to June—and up 5% year-over-year. While orders slowed this July, they are 87% higher than this time in 2021.

Fleet customer demand for trailers is large, according to Eric Crawford, ACT VP and senior analyst, said based on conversations he and McNealy have had with trailer builders. Those OEMs would build more if they could, Crawford said.

"Labor was cited universally as a constraint," he said. "Among many, it was a primary constraint."

It wasn't just the trailer builders having trouble finding, training, and retaining labor to manufacture new units but also the OEMs' suppliers. "So it was almost like a double whammy from that standpoint," she said. "On the parts, they've learned to adapt because it's not all parts across the board—it's a rolling thing."

She said this supply chain struggle forced trailer OEMs to adapt and rework their businesses. But OEMs reported to ACT Research that supplies are improving.

"We started to hear that supply chain conditions were starting to ease and that inflation was being passed through," Crawford said. "Trailer OEMs have been repricing their backlog prior to building by reaching out to the customers. As far as the customer is concerned, there hasn't been much pushback at all. Everyone understands the inflationary environment that we're in."

The order backlog and improved supply chain created strong conditions for trailer OEMs going into 2023. But could a freight recession or other economic conditions change that? "We think '23 is going to be just fine," Crawford said. "But there's a risk factor there."

Those risks include inflation and the intensity of the looming recession.