GRAND RAPIDS, MI. Could the North American trucking market be approaching a watershed moment with disc brake adoption? The heavy trucks and trailers of all kinds across the United States predominantly are wearing big drums today, though trucking here did once try out discs. That first go-round apparently didn't go so well.

"To be honest, the product was not ready," says Bill Hicks, director of product planning, Americas at SAF-Holland, a global manufacturer of trailer suspension/axle systems, fifth wheels and other heavy truck parts. For trucking, disc brake technology began to cross over in part from the automotive sector.

Hicks recalls his first experience with disc brakes in the U.S. "My first bout with disc brakes in North America was with my 1977 Plymouth Volare that had brake calipers that were made out of plastic and would seize up. I'd be going down the road and would literally have no brakes," he says. Early problems with disc brakes still had to be overcome, and they didn't catch on in the North American trucking market in their initial appearance prior to the turn of the millennium.

Yet today, all of the highest performance cars have disc brakes all around for the shortest stopping distances. The technology clearly marched on, and despite its initial faltering in North America, disc brakes on trucks saw much more development and improvement in the European market.

That was bolstered in 1996 when Daimler introduced its Actros truck with standard disc brakes in Europe, notes Steffen Schewerda, president of SAF-Holland Inc. and SAF-Holland Americas, and despite considerable skepticism of the move, "they pulled it off." Even so, the learning curve for disc brakes and trucks still proved steep and costly.

"What we saw in the market and what we experienced in the entire industry was a lot of problems with heat," Schewerda says. "In the time frame between 1996 and the 2000s, we saw major problems; in those days, 60% of discs were exchanged because they cracked and didn't wear. There were massive heat cracks in the discs, even to the point where the comparable highway authorities in Europe pulled the trailers off [the road] and said, 'You cannot go with these things.' Whole chunks of discs were flying off on the highway, and it wasn't safe."

Better heat dissipation came about through things like venting discs and other innovations such as SAF's INTEGRAL rotor, which expands more uniformly when heated to keep the braking surface flat while conventional rotors suffer from what's known as the "umbrella effect." That causes conventional rotors to curve to the outside when heated, creating an uneven surface like an umbrella and making rotors susceptible to heat cracks.

By around 2005, Schewerda contends, "we were over the problems" with disc brakes in Europe. "Everything that can go wrong probably did go wrong in Europe, and we don't want to make the same mistakes here in North America," he adds.

Better performance

Why are disc brakes better? Hicks begins that discussion noting that as you use your brakes, they get hot. With drum brakes, you've got shoes at a fixed point inside pushing out against the drum to stop the vehicle.

So the drum gets hot, and as it does, it actually expands and grows away from the shoes, which then have to travel farther to make contact with the drum and stop a vehicle like a heavy truck, requiring more brake pressure and causing "fade" or loss of performance.

With disc brakes, even as the rotor gets hot and expands, it only gets closer to the brake pads and pushes harder. Provided the brake system can take the heat that a loaded tractor-trailer can generate when stopping, overall brake system performance is much improved over drums.

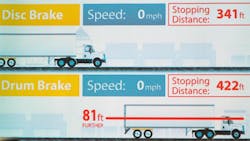

Hicks notes that in testing two conventional tractor-trailers against each other, both with drum brakes on the tractors and one trailer with drum brakes and the other with discs, SAF-Holland found the truck with disc brakes stopped from 75 mph in 341 ft. The truck with drum brakes on its trailer made the same stop in 422 ft. — fully 81 ft. farther, which is roughly the height of a seven or eight-story building.

"I don't want to be dramatic, but that's life and death," Hicks says.

The cost hurdle

So what's keeping disc brake adoption from catching on in the North American trucking market? Simple: the upcharge.

SAF-Holland believes it has come up with a product that will help fleets not only boost braking performance significantly but do the math in terms of up-front investment and total cost of ownership. "The problem the industry is facing is the initial cost," says Schewerda. "Fleets are convinced that yes, it is the better technology; it does make sense. But what about the initial cost?

"Up till now, there is a prohibitively high threshold in terms of premium when the trailer OEMs price products to the market," he continues. "We truly believe we can change the picture here; we are working on the OEM side and on the fleet side to get a penetration here in North America which is basically double or triple where we are today."

Like the introduction of Daimler's Actros, SAF-Holland believes its new P89 Air Disc Brake Series could be the spark that catches fire for disc brakes in this trucking market. With a drums-vs.-discs comparison for trailers, the company says fleets typically face about a $900-$1,200 upcharge per axle for disc brakes, and the New P89 value-oriented model offers a 5-year warranty for a good chunk less: around 40% lower acquisition cost.

The premium P89 Plus model, meanwhile, comes at a cost similar to that typical upcharge, but offers a 7-year warranty and other performance and maintenance improvements like a design that eliminates traditional wheel seals — SAF-Holland engineers identified those as a common source of maintenance issues — and offers lower rolling resistance for better fuel economy.

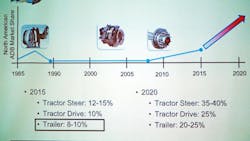

Adoption of disc brakes on tractor-trailers has been growing in the North American market, and if the folks at SAF-Holland are right in their predictions, the trucking market here may be on the verge of a watershed moment in switching to discs over drums.

"When you look at the tractor side, the penetration is already growing, but slowly; on the trailer side, not so much," Shewerda says. "But we truly believe the time is ripe — that's why we've introduced the P89 Series."