2025 Powertrain Outlook: Integration is the keyword as manufacturers roll out new solutions

Many factors drive powertrain development for heavy-duty trucks and tractors. There are increasingly more stringent emissions requirements, which impact engine, transmission, and drive axle designs. There are also fleet demands for increasingly better drivability and fuel economy, coupled with the need to lower costs by facilitating more effective and predictive maintenance practices.

For truck, engine, and drivetrain manufacturers, integrated powertrain solutions have become the best way to meet these needs.

What powertrain developments are available now and what's coming soon? What benefit does collaboration between engine and drivetrain manufacturers and fully integrated OEM powertrain solutions offer fleets? Are telematics systems playing a more significant and growing role?

Recently, FleetOwner posed those questions to manufacturers of powertrains for heavy-duty commercial vehicles:

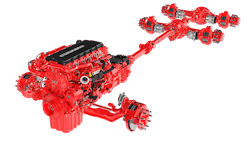

Cummins

The technology and capabilities of Cummins drivetrain and braking systems are focused on fully integrated powertrain solutions and providing customers the ability to customize their powertrain specs to suit their business requirements best, noted Jim Nebergall, executive director of market strategy.

“Cummins values the close relationships we have with truck manufacturers throughout our product development cycles,” he said.

An example is the Eaton Cummins Endurant HD and XD series, which has been optimized for the next-generation X15 powertrain. Another integration is Cummins-Meritor Drivetrain Systems products with 14X HE tandem drive axles that feature super-fast ratio options for the ability to handle the high torque demands of downsped engine platforms.

“This past fall, Cummins, Bosch, and KPIT announced a collaboration to provide smarter and simplified telematics solutions,” Nebergall also related. “The project has the potential to significantly reduce the time and cost required to develop telematics applications that access and update vehicle ECUs. The launch of Open Telematics is positioned to be central to streamlining operations for OEMs. We’re excited to have collaborated with industry partners to release open software to industry suppliers.”

Detroit

Recent updates to Detroit powertrain offerings, according to Len Copeland, product marketing manager, include new engine ratings to maximize fuel efficiency and performance. “Specifically, our 425 horsepower, 1,750 lb.-ft of torque rating increases responsiveness compared to the previous version with a 400-horsepower rating,” he said.

“With this rating update, we were able to maintain the cruise RPM, ensuring that driving fuel economy is still maximized while increasing acceleration rates by delivering horsepower and torque faster in the RPM band,” Copeland added.

“In 2025, we will carry forward the same engine and powertrain offerings,” Copeland continued. “One small change is being made to the DD15 engine’s aftertreatment to reduce NOx emissions. This technology was originally developed specifically for the DD13 engine in omnibus states, and we adapted it to the DD15 because it makes sense. The change will have no impact on power or fuel efficiency, just an overall reduction in emissions footprint.”

Copeland also pointed out that Detroit's fully integrated approach to powertrains extends beyond engines, transmissions, and axles. “Safety systems and connectivity solutions are seamlessly integrated to help deliver operational efficiency,” he said. “For example, engine brakes are intelligently linked to safety systems, enabling smooth and controlled deceleration when using adaptive cruise control.

“Additionally,” Copeland related as well, “the transmission communicates directly with the engine to optimize torque during vehicle launch, ensuring maximum starting performance while minimizing wear on the clutch and driveline.”

International

International’s product development benefits greatly from collaboration, and the new S13 integrated powertrain is a prime example, related Jonathan Hutchison, senior powertrain launch manager.

The first customer deliveries of the International S13 Integrated powertrain began in early 2024. Available in the manufacturer’s LT, RH, HX, and HV Series vehicles, the solution is comprised of a 515-HP S13 engine, fully automated 14-speed overdrive T14 transmission, and an aftertreatment system designed to maximize integration.

“We’re thrilled to expand our vehicle portfolio with the S13 Integrated Powertrain to include HV515 and HV615 models in 2025,” Hutchison said. “With seamless body integration with International PTO offerings, the powertrain solution will also ensure easy up-fitting.”

Mack Trucks

A fully integrated powertrain manufacturer for over a century, Mack Trucks has long produced its own engines, transmissions, and rear axles. “The benefits of this integrated approach include enhanced uptime and optimized service,” said Joseph Scarnecchia, powertrain sales development manager. “Today as well, seamless integration of a fully integrated electronic architecture ensures optimal communication between all components, eliminating compatibility issues with multi-vendor solutions.”

Mack’s most recent powertrain innovation for long-haul trucking operations consists of the Mack MP8 445HE Turbo Compound engine, Mack mDRIVE 13-speed overdrive transmission with crawler gear, and a high-efficiency drive axle featuring a 2.15:1 ratio.

“This powertrain is optimized for carriers operating at highway speeds above 63 MPH and consistently running at or near maximum gross vehicle weight of 80,000 lbs.,” Scarnecchia explained. “It’s an example of how an integrated powertrain solution maximizes fuel efficiency for highway applications while maintaining the power needed for fully loaded operations.”

Paccar

For 2025, related Kyle Kimball, Kenworth director of marketing, the manufacturer will continue to provide a suite of engine and powertrain offerings designed to meet challenging regulatory and market needs. “With 2024 having been the key emissions year and having launched CARB-compliant engine offerings like the MX-13 and X15N, we ‘re now focusing on 2027 emissions and ensuring that our engine and powertrain technologies will meet the upcoming NOx standard,” he said.

Looking ahead as well, Kimball noted, telematics systems will play a larger role in powertrain service.

“Telematics data available to our customers through Paccar Solutions helps provide insights that ultimately inform them of maintenance requirements and potential downtime events,” he explained further. “At the same time, Paccar MX Prognostics is helping dealers and fleets perform targeted preventive maintenance before a truck goes down or fault event even occurs.

“The value of an integrated powertrain is that it provides a comprehensive, optimized, and efficient package,” Kimball added. “That gives fleets peace of mind.”

Volvo Trucks North America

With the announcement of the all-new Volvo VNL truck, Volvo Trucks North America President Peter Voorhoeve referred to the new Class 8 model as more than just a facelift. “This is a platform for all future powertrain solutions,” he said.

For the VNL model powertrain, Volvo introduced design enhancements to the D13 engine, including a new wave piston with a shorter piston height, as well as a longer connecting rod; smaller injector needle control valves; a variable vane oil pump, and improvements to the turbo compounding unit and turbocharger.

To further drive integrated powertrain benefits, the manufacturer introduced changes for its I-Shift transmission that improve shift speeds by up to 30%. The increase in shifting speeds was achieved through an overhaul of the software, electronics, clutch mechanisms, and precision engineering. Engineers at Volvo Trucks redefined algorithms, reduced clutch throw, and developed an enhanced clutch brake system to revolutionize gear shifts, significantly reducing the transition times between gears to ensure seamless power delivery.

“Vehicle efficiency transcends mere engine performance; it encompasses the synergy between various components, where the transmission plays a pivotal role,” said Duane Tegels, product marketing manager for powertrain. “The transmission's ability to optimize gear shifts, reduce energy loss, and harmonize power delivery significantly influences overall vehicle efficiency, showcasing that a holistic approach beyond the engine is vital in achieving optimal performance and fuel economy.”

Allison Transmission

“We continue to advance our fully automatic transmissions and partner with OEMs to meet their unique needs and those of our fleet customers,” said Branden Harbin, executive director of global marketing and external communications. “For example, we introduced a new 9-speed fully automatic transmission for heavy-duty vehicles that operate in stop-start duty cycles.”

Built on the Allison 2000 Series, the transmission features nine forward and three overdrive gear ranges. Following initial deliveries of the new transmission in Europe, the first launch with a major OEM in North America will be announced in March.

Allison has also partnered with Cummins to test and validate the new Cummins X15N 15-liter natural gas engine paired with an Allison 4000 Series fully automatic transmission. Mating the 4000 Series with the X15N delivers fuel savings and emissions reductions for fleets, according to Harbin, reducing total cost of vehicle ownership while optimizing vehicle performance.

Harbin also pointed out that as telematics and prognostic technology advances, they are becoming valuable tools for fleets in proactively managing the health of their vehicles. Allison, he added, is engaged with a number of OEM partners to support predictive insights that prevent or reduce costs associated with unplanned vehicle downtime.

“Collaboration between OEMs and engine and drivetrain manufacturers will be critical in advancing commercial vehicle technology to meet the needs of fleets,” Harbin stated. “These partnerships will enable manufacturers to manage development costs as well as leverage their unique technologies and expertise to deliver industry-leading solutions.”