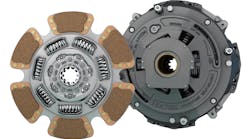

LAS VEGAS. The newest generation of the Advantage Series heavy-duty clutches from Eaton have received a number of design upgrades intended to improve performance in low-RPM downspeeding applications as well as provide better shift performance, reduce vibration and chatter, and make it easier to monitor clutch wear.

Introduced during Heavy-duty Aftermarket Week, both the Eaton Advantage Self-adjust and Easy-pedal Advantage have been fitted with soft-rate spring dampers to prevent driveline damage in powertrains speced to deliver improved fuel economy through downspeeding. By better isolating driveshafts in low RPM/high-torque conditions from engine combustion pulses, the softer damper springs can improve driveline durability while handling torque ratings up to 1,850 lbs. ft., according to Ben Karrer, global product strategy manager at Eaton.

A second wear tab indicator added to the self-adjust model will make it easier for shop personnel to visually inspect the clutch for wear, he pointed out.

Other changes for both Easy-pedal and Self-adjust Advantage clutches include a new strap drive system said to eliminate lug fatigue wear and rattle when the clutch is disengaged. A new spring separator system is designed to deliver quicker disengagement for smoother shifts.

Torque ratings for the newest Advantage heavy-duty models range from 1,650 to 2,250 lbs. ft. The Self-adjust Advantage is covered by a 3-year/350,000-mi. warranty and the Easy Shift by a 2-year/unlimited-mi. warranty.