ORLANDO, Florida—Parts and labor cost data indicate that significant cost challenges continue to impact fleets through 2023. The good news, however, is that these cost increases slowed by the end of 2022 compared to the previous year, according to the latest data from American Trucking Associations’ Technology & Maintenance Council and Decisiv.

The latest quarterly Decisiv/TMC North American Service Event Benchmark Report was released during TMC’s 2023 Annual Meeting here. On a year-over-year basis between the fourth quarter of 2022 and Q4 2021, parts and labor costs rose by 14.4% and 10.8%, respectively, and combined expenses were up 13%. Earlier in 2022, annual comparisons between quarters showed that combined parts and labor costs were up 15.3%, parts costs rose 15.8%, and labor expenses increased by 14.6%.

See also: More TMC 2023 coverage from Orlando

“The overall positive improvement in parts and labor costs shows that despite economic headwinds and supply change challenges, commercial vehicle service operations continued to successfully offset increases driven by factors outside of their control,” said Dick Hyatt, president and CEO at Decisiv.

Declines in costs also were apparent in comparisons between Q3 and Q4 of 2022. In the fourth quarter of last year, service operations saw a 1.6% decline in parts costs while labor expenses rose by less than one-half of a percentage point (0.4%) Overall, combined parts and labor costs from Q3 to Q4 were down 0.9%.

The latest data is a clear indication of a trend toward lower service costs as well as total cost of ownership for fleets, according to the report. However, as it is unlikely that lower parts prices and reduced labor wages are responsible, other factors are most likely influencing cost decreases, Decisiv noted.

Those include a slowing of for-hire truck tonnage during the final quarter of 2022, resulting in decreased mileage. Additionally, after being hampered by supply chain issues, manufacturers have seen marked increases in production levels of new trucks. As pent-up demand continues to drive up orders of replacement vehicles for aging fleets, new equipment will positively impact their bottom line by requiring fewer repairs and high-cost unscheduled service events.

These market trends, coupled with the drive to reduce downtime, have helped drive the evolution from service management to asset management.

“Increasingly, we want to look at how you proactively manage those assets,” Mark Wasilko, Decisiv's VP of marketing, told FleetOwner. “As you evolve to asset management you want to get ahead of it, and you want those alerts and diagnostics to be received whether you’re a fleet leasing company or you’re a dealer providing managed care.”The report also indicates that for the years 2021 and 2022, parts and labor costs continue to run about 10% higher in the Western region of the U.S. compared to the other four regions and Canada. Equally split between higher parts and labor costs (10.8% and 10.3%, respectively), the increases may be the result of lingering higher parts prices as well as higher labor rates in areas where competition for technicians remains fierce.

VMRS system insights

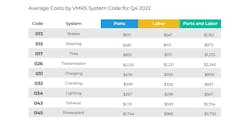

In the data that Decisiv collects for the TMC Benchmark Report, the nine Vehicle Maintenance Reporting Standard (VMRS) system-level code categories tracked account for 61.25 % of total parts and labor costs.See also: Heavy-duty repair report shows shop revenue recovery, higher technician pay

Of particular note, according to the report, combined parts and labor costs for cranking systems saw the largest increases between Q3 and Q4 of 2022 of 3% and year-over-year between Q4 2021 and 2022 of 21.1%. The year-over-year increase was driven primarily by a 29% increase in parts costs, which isn’t surprising considering the extreme shortage of parts and rising prices due to inflation in much of 2022.

Excluding tires, brakes, and lighting systems where costs reflect mileage and routine maintenance requirements, other VMRS categories did indicate year-over-year average parts and labor cost increases for most likely the same reasons they did for cranking systems. Included were charging (17.5%), power plant (16.3%), and exhaust (12.6%) systems.

Combined parts and labor costs for steering systems saw the largest decrease between Q3 and Q4 of 2022 at 11% and a slight year-over-year increase between Q4 2021 and 2022 of 1.6%.

When it comes to the widespread use of VMRS data, Jack Poster, TMC’s VMRS services manager, told trade press that a lot of people are using it but don’t know it. Suppliers and manufacturers are also using VMRS data more and more.

“I am getting calls and emails from nontraditional fleets, states, utilities, cable companies, construction companies, and concrete mixing companies that want to use this,” Poster said. “The question I’ve often asked is who is using it correctly, that’s the key. Just because you’re using it doesn’t mean you’re using it correctly.”

The Decisiv/TMC North American Service Event Benchmark reports are generated using data from the Decisiv SRM platform on service and repair events for more than 7 million commercial assets operating across the U.S. and Canada.

Cummins-Meritor, Phillips Industries join Decisiv SRM

In addition to its benchmarking report, during TMC 2023, Decisiv, which provides service relationship management (SRM) solutions, announced that Cummins-Meritor’s and Phillips Industries’ digital inspections will be available to the more than 5,000 service provider locations and fleets that use the Decisiv SRM platform.

Inspections are available on any connected device and include:

- Step-by-step inspection tasks recommended repairs, and links to instructions that enable a more thorough analysis and maintenance recommendation, regardless of technician experience.

- Allowing service providers to more precisely inform fleets of critical repair requirements and provide more accurate estimates of repair costs and time.

- Improving compliance with DOT inspection requirements.

The newly integrated digital inspections enable technicians to validate the proper and safe operation of Cummins-Meritor and Phillips components. The integration enabled by Decisiv allows the manufacturers to provide standard repair operations and change or supplement inspection procedures immediately and as needed, according to Decisiv. The solution identifies component issues based on inspection information entered by technicians and automatically creates a service event case in the Decisiv SRM platform.