With the increase of hybrid and battery-electric tractors on the road, it’s time for the commercial vehicle maintenance sector to get up to speed on electric axles, or e-axles, and what to expect in terms of maintenance.

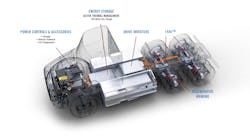

The first thing to know is what an e-axle is. This drivetrain system consolidates several of an ICE vehicle’s major systems into one, including the motor, transmission, power electronics, and brakes. The motors also serve as regenerative brakes, which assist with stopping, as well as redirect that kinetic energy to the battery.

“You’ve got a lot of content that’s being condensed into a small package, and replacing a diesel engine and conventional transmission and driveshaft opens up all sorts of opportunities,” explained Jeremy Freznick, senior director of commercial vehicle engineering at Dana Inc., one of the more active OE’s developing and manufacturing e-axles, with options for medium- and heavy-duty trucks, vans, and buses. “That’s whether you want to use that [space] for additional payload or to package additional batteries in that space to get extended range.”

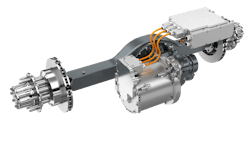

Dana’s eS9000r e-axle for medium-duty hybrids and EVs weighs 815 lbs. Its standard battery pack setup allows Classes 4-6 trucks and buses to run for up to 170 miles between charges. The first of Dana’s Spicer Electrified Zero-6 e-axles line will also be used as the drivetrain for the Freightliner Custom Chassis Corp. (FCCC) all-electric MT50e medium-duty last-mile delivery vehicle. According to Hyliion, the Hybrid eX will also use Dana's e-axle propulsion system.

Automatic transmission manufacturer Allison Transmission also has thrown its engineering prowess into the EV sector. The Indianapolis-based company now offers the eGen Power 100D e-Axle for 6x2 tractors and eGen Power 100S for 6x4’s and heavy-duty straight trucks, along with buses and medium-duty trucks. Like their burly fossil fuel-guzzling cousins, Allison’s leaner e-axles boast plenty of muscle.

“The eGen 100D features two electric motors, each capable of generating greater than 200 kW of continuous power, with peak combined power of 648 kW,” Allison CTO Michael Foster noted. “This is similar power to a 15L engine paired with a 4000 Series Allison transmission, but packaged in the space claim of a traditional axle. The eGen Power 100D also integrates a two-speed gearbox in the central housing, optimizing the e-axle to enable the high starting gradeability to get heavy loads moving, while also offering the benefit of superior efficiency at cruise speed.”

Hino Trucks will be the first OEM to use Allison’s eGen Power 100S e-axles, which will be spec’d on Hino’s Classes 6-8 battery-electric trucks.

These are just two examples. Others include Bosch, Detroit, Eaton, and Meritor, though even that list is not exhaustive.

Say goodbye to maintenance?

What’s not exhaustive is the list of preventive maintenance items: no oil changes, fuel injector replacements, diesel exhaust fluid, nor cleaning of the diesel particulate filter, a maintenance bane of many a diesel technician.

Some OEs are claiming certain products can be virtually maintenance-free under the right conditions, but for most, there are at least a few infrequent lube changes in terms of preventive maintenance. According to the OEs, any PMs for the e-axle are more than offset by the elimination of the aftertreatment system in diesel trucks.

“Technicians can expect reduced maintenance from an e-axle when compared to a traditional powertrain,” Foster asserted. “There are less moving mechanical components in an e-axle, which results in less friction and less wear and tear, leading to increased durability and a longer axle life.”

Allison’s regenerative braking system and gear layout “allows for maximum efficiency and 100% regeneration torque capability,” which does reduce brake wear, but Foster noted the actual brake components, such as roots and pads, will still require periodic maintenance.

All told, the benefits include reducing downtime, maintenance costs, and total cost of ownership, Foster surmised.

The real work for fleets will be in spec’ing the right e-axle, ensuring it provides the best performance and range. How to do that will be a bit more complicated than the maintenance.

Everyone joining in

As far as spec’ing, a fleet will have many different options from which to choose. Like Allison, fellow transmission maker Eaton has also diversified into e-axles. Eaton’s eMobility business announced a 4-speed heavy-duty transmission for EVs at the NACV show in 2019. Julie Marshaus, manager of new product introductions and systems, eMobility, for Eaton, said that the HD 4-speed transmission design is progressing well.

“It is heading to B-samples shortly and is still targeting full production in 2023,” Marshaus said. “The HD 4-speed is intended for the Classes 6-8 market, with the capability of 2,600Nm input torque at 5,000 rpm. The transmission is capable of the typical applications in this class of vehicle, with expected markets in drayage and regional haul. It will easily expand to linehaul when that application is more viable for the EV space.”

So how does an Eaton e-axle differ from say, the Eaton Cummins Endurant automated manual transmission?

“The major difference is that the EV transmission only needs four gears, and because electric motors spin backwards, the reverse gear and idler assembly have been removed,” Marshaus explained of Eaton’s EV transmission design. “The torque curve for electric motors is peak torque at zero speed and is very flat.

“This allows the transmission to use fewer gears because we do not have to shift to maintain a diesel engine in the peak torque range of 1,800 rpm as conventional transmissions are required to do for drivability and efficiency,” she continued. “Regarding efficiency, the electric motors have peak efficiency at the higher rpm bands. Therefore, the transmission holds the top input speed as long as possible before shifting to maximize the vehicle efficiency.”

The differences are found in of course the components and design, but also the efficiency and performance, as well as maintenance requirements.

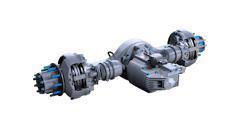

Meritor is currently developing three different electric powertrain platforms: the 12Xe, 14Xe, and 17Xe.

“The bigger the number, the bigger the vehicle that it’s intended to cover,” explained John Bennett, VP and CTO at Meritor. “A 12Xe has an integrated electric motor and two-speed transmission, focused on Class 4 and 5 vehicles. Our 14Xe—Class 6, 7, and then can be used as a tandem for Class 8—also has an integrated electric motor and a two or three speed transmission. The 17Xe is targeting heavy Class 8 as a single axle, so European applications which are predominantly 4x2 or 6x2, using a single driving axle. The 17Xe has a much larger motor and a larger integrated transmission available as both a two speed or a three speed.”

The 14xe is being used as the e-axle for Hyliion’s ERX truck.

Bennett noted that the transmission can also be configured as a single speed.

“Right off the bat you’ll notice, compared to a diesel engine mounted to an automated manual transmission, that the number of speeds is significantly reduced,” Bennett said. “The reason for that is an electric motor has a very wide speed range in comparison to diesel engine, and it’s very efficient across the majority of that speed range. In our 17Xe, for example, the electric motor can run up to 5,500 rpm, and it’s efficient; and by efficient, I’d say over 92% efficient for about 80% of that range. So, it’s highly efficient, as opposed to a diesel engine… That’s a big difference with an electric powertrain—you can get away with, in some cases, a single speed, but in most cases of the heavy-duty vehicle, two or three speeds, and that’s it.”

Diagnostics

Utilizing diagnostic software will remain standard practice when servicing electric powertrains and e-axles. Bennett explained that a familiar process will still exist with diagnostics, as plugging in a diagnostic tool “will flash fault codes and indicate which areas are problematic or need to be serviced. That’ll give a technician a pretty easy indication, very similar to today, of where to look and where to go, and what things to service, potentially.”

Understanding how the system functions lends to being able to accurately diagnose performance issues.

“The controls themselves are a bit more complex,” Bennett heeded. “The mechanical parts are simplified. The parts that are there are very conventional. There’s no clutch in these systems. It’s essentially gears, shafts, and bearings.”

Bennet said while the shift rail, shift collar, and actuator will be familiar to technicians, the controls, which are clutch-less, are more complex, similar to an AMT.

“You’re doing synchronization of the motor speed; you’re essentially taking the motor and going into a speed mode, releasing the torque, shifting into a neutral position, then you either spin up or speed down the electric motor, depending on which way you’re shifting, and re-engaging the shift collar,” Bennet explained. “So, it’s really coordinating and synchronizing the electric motor which is done through your motor controls. From a system standpoint, it’s going to be very simple to diagnose and easy to service.”

When dealing with Meritor’s “Xe” platform, especially because it will be connected to either a fuel-cell vehicle or EV, higher voltages must be considered. Proper safety training and personal protective equipment must be paramount. However, the transmission itself is not utilizing higher voltages.

“It’s only low-voltage connections to the actuator and the sensors,” Bennett said of transmission service considerations. “The transmission on our ePowertrains can be removed without really touching any of the high voltage system whatsoever, so it’s simple, from that standpoint… The electric motor is integrated into the axle itself, but the high voltage goes through the motor, the inverter in the battery pack. Our transmission mounts on as a self-contained sub assembly, and it can be removed that way. So, disconnecting the low-voltage sensors and cable, and then popping off the transmission as a sub assembly is the way to service it.”

Fleets need not expect any specialty tooling or equipment, beyond up-to-date diagnostic software, to service EV transmissions.

“One key benefit of EV transmissions is that technicians and fleets already have all of the tools and knowledge required to service them,” Marshaus said. “The EV transmission, with its four forward gears, no back box, no clutch, and no clutch actuator, has greatly simplified the overall drivetrain service strategy. The transmission will only need an oil change on a PM schedule and regular troubleshooting in case of a failure.”

“There are no unique tools that are required,” Bennett agreed. “A standard mechanic’s toolkit would suffice. You need tools; you’ll need wrenches, and sockets, and whatnot, to take it apart and disassemble it, but nothing out of the ordinary… A certain diagnostic tool will be required. In many cases, the service shop will have that tool, but in the event that they don’t, that is a unique tool; but once you get into the transmission itself, it’s the standard mechanical stock tools that everybody would have.”

Lubrication needs

With fewer moving parts, there’s also less of an emphasis on lubricating them.

“Electrified transmissions will have fewer mechanical components and will require longer drain intervals compared to conventional transmissions,” said Penney Do, product technology specialist at Chevron, who has been developing e-axle and electric powertrain lubricants. “Those units will require less frequent and extensive services and will need less volume of fluids for servicing them during their effective lives.”

It is important to note electric powertrains and e-axles may require special lubrication fluids.

“As electrification of driveline systems (including transmissions and axles) is getting more widely developed by OEMs at different parts of the world, Chevron is partnering with them to develop the right fluids for their evolving hardware in this space,” Do said.

Allison’s will require longer drain intervals compared to conventional transmissions.

“Depending on the duty cycles and vocation, the fluid and filter of the e-axles may last for a vehicle’s lifetime,” Foster said of the eGen line.

When it comes to the lubrication of the electric powertrain, and specifically the transmission, Meritor has simplified the design and runs the axle lube through the transmission system.

“Generally, the transmission will run on different fluids, automatic transmission fluid, for example, or some other fluid that’s different than the axle lube,” Bennett explained. “Because our system is fully integrated and we didn’t want to have to service multiple lubes, it’s just one oil, and it’s typical axle oil that runs through the whole integrated system. We did that for ease of maintenance.”

Dana also has simplified e-axle lubrication for fleets.

“The only standard maintenance that’s required on our e-axles is your traditional axle lubrication interval,” said Freznick, who added Dana also utilizes special lubricating fluid. “You do have to pay attention to some of the powertrain cooling fluid intervals, which are typically 100,000 miles.”

Traditional gear oil is used in the differential, though, and has the same gear lube interval change as a traditional axle.

“You’ve got a typical drain plug you pull; catch the gear oil like you would with the traditional axle,” Freznick advised. “You change your coolant every 100,000 miles and you’re good to go.”

Freznick stressed that wiring and cable checks will need to be added to the inspection list.

“There’s a high voltage interlock that is the job one would do before performing any kind of checks or maintenance,” he said. “Basically, it shuts down the high voltage cable and de-energizes the system. You want to de-energize your system before you’re doing any of that maintenance work.

“There is always some hesitation because it’s new,” Freznick attested in regard of the adoption of e-axles. “But, the majority, if not everybody who’s been through the safety training understands, what you need to do is provide a safe work environment. Everybody feels very comfortable with the systems at that point. Once the newness wears off, and you can appreciate that, really, once you de-energize the system, things are just like you would expect with a traditional drive axle and drive shaft.”

This article originally appeared on Fleet Maintenance.