ORLANDO, Florida—Mitchell 1 updated its TruckSeries repair information platform with two new digital tools to help commercial vehicle technicians. A time management tool designed to bolster shop productivity and an improved wiring diagram tool to assist with electrical diagnostics and repairs were announced at American Trucking Associations' Technology & Maintenance Council annual meeting.

Both features added to Manager SE Truck Series software, which is used to help service Classes 4-8 trucks, were developed to help technicians work smarter and more efficiently as the transportation industry becomes more complex and high tech, said Ben Johnson, Mitchell 1 director of product management.

These advancements include more efficient advanced driver assistance systems (ADAS), diesel engines, electric drivetrains, and autonomous trucks.

“With these new technologies, maintenance technicians will experience a lot of ‘first-time’ events in the repair shop with no experience to draw upon,” Johnson said. “What this means is that techs on the front lines will need to adopt a proven electronic diagnostics strategy to succeed in repairing and maintaining fleets with these advanced technologies.”

Wired Up

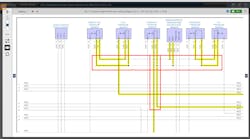

The Advanced Interactive Wiring Diagrams update addresses a way to more quickly resolve issues within the truck’s electrical systems. Now technicians can search for and identify connectors, grounds, and splices in a more interactive way.

Other improvements include a dropdown history that shows the previous 10 diagrams viewed in a session.

The exclusive feature allows a technician to navigate via the diagram directly to repair information for components. The component names are hyperlinked to the information a tech needs, such as location, connector views, and replacement procedures.

“As a technician, I can very quickly focus in on what I want to see. I can dim the rest of the wires so that I can focus even better,” Johnson explained. “Now I can zoom in and see what I'm interested in looking at.”

Prompts also give warnings, such as that the fuel is under high pressure and that the fluid is hot and could cause burns. Parts and repair information is displayed. The feature also works in conjunction with diagnostic tools such as a multimeter or digital oscilloscope.

Johnson said this is vastly different than the old days of Mitchell’s thick brown books, where a tech would bookmark a page, find additional information about the sensor somewhere else, and then continue on the task. Digital diagrams also had efficiency issues.

Time Management

Mitchell also provided a way to get technicians in general to better use their time on the job.

When Johnson was a technician, he would punch a clock to track his time at work. That method merely showed that Johnson was physically in the shop, not necessarily how productive he was. The number of repairs he completed would track that, along with how much he would be paid.

He would get an unpleasant surprise some paydays when he learned all that time chatting it up at the parts counter led to less billable hours.

“If I didn’t pull my weight, the shop was less productive than it could have been,” Johnson noted.

The update is now available for Mitchell 1’s Manager SE Truck Series software and provides shop management with new ways to measure technician productivity they can use to enact change.

Accessible through smart devices, the software automatically generates productivity statistics as technicians clock in and out of labor operations, and it also enables users to track and report employee shift hours in real-time on mobile devices.

“Once they log in, they can do the same things I used to do with that old-time clock—they can clock in when they get there, they clock out when they leave for lunch,” he said. The sign-in feature is geofenced so a tech cannot clock in or out from home or somewhere else.