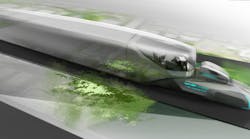

NEWPORT, RI. The heavy-duty truck of the future could be a tractor with no physical fifth wheel but only wireless connections to a train of smart self-propelled trailers, according to Jeff Cotner, chief designer, exterior for Volvo Trucks North America. Such smart trailers could disconnect themselves from the road train, traveling the last mile to a final destination autonomously, he told an audience of dealers and fleet customers at a symposium here during a stopover of the Volvo Ocean Race.

“Maybe the tractor is just an air splitter with no visible connection to the trailer or a platoon of trailers,” Cotner speculated. “Trailers with brains and propulsion of their own could slipstream tightly and automatically open up gaps when needed to maneuver. You could even combine passengers and cargo in this kind of train.”

Following that line of speculation, Cotner suggested the truck of the future might actually be purchased as a system with a powered platform that could accommodate a variety of cabs depending on a fleet’s immediate requirements. “Then you’d have options and it would be simple to just snap together.”

Connectivity has already begun to transform the trucking industry, according to Goran Nyberg, president of Volvo Trucks NA. Pointing out that those under 25 have never lived in a world without the Internet, he said “They have an expectation of constant connectivity.” Drivers and managers of the future “will have far different expectations when it comes to connectivity. We need to find attributes that not only bring new value to our businesses, but also attributes that attract those new drivers.”

The push for greater connectivity will involve machine-to-machine communications as much as between individual, Nyberg said in an interview following the symposium. “Data [from M2M connectivity] will mean more decisions made with different references and parameters,” he said.

For example, Volvo’s remote diagnostic system, which now covers a network of 80,000 trucks, delivers a great deal of data before and after a recorded event. “That means we can get more precise about what needs to be done, that we can make better decisions that get the truck back in service sooner,” Nyberg said. “And the value of more data will extend beyond diagnostics.”

Having launched the remote diagnostic service in 2012, Volvo “quickly understood that customers wanted solutions, not more data,” he said. “Fault codes are not of interest, but rather they want to know when can they have the truck back on the road.”

And whether it involves the truck’s mechanical systems or the fleets’ operational priorities, fleets “want connectivity solutions, not data,” Nyberg said.

“Connectivity, I believe, will be the next game changer for the industry, and not in five years or in four years, but in the next two or three years,” Nyberg said. “This is about to change the industry, the way we work, the way we communicate. I think we are facing very interesting times and we’ve decided to become a leader when it comes to connectivity.”