Eaton’s Vehicle Group has formed a new ePowertrain business unit, which will focus on products from Eaton’s electrified vehicle (EV) transmission, reduction gearing, and differential portfolios.

Combining the product lines into a new ePowertrain business unit aims to align Eaton’s powertrain and EV experts and allow the Vehicle Group to offer its global customers solutions for commercial and light-duty EVs.

“Automakers face many challenges when developing an EV powertrain, such as optimizing efficiency, weight, and noise, vibration and harshness (NVH), and dealing with packaging constraints,” said Anthony Cronin, product director of EV gearing and differentials for Eaton’s Vehicle Group. “Eaton can help manufacturers overcome these challenges by utilizing our many years of experience and in-house capabilities in design, validation and manufacturing of high-precision, high-quality gearing transmissions and differential solutions.”

Range and performance

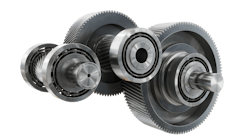

Eaton’s portfolio of multispeed transmissions includes 2-, 4- and 6-speed electrified commercial vehicle transmissions. Eaton said its EV transmissions are based on layshaft architecture typical of automated manual transmissions (AMTs) and shifting is synchronized without a clutch using a traction motor.

Unlike direct-drive transmissions that have long been the standard in EVs, Eaton’s transmission portfolio aims to offer greater efficiency at high speeds as well as increased torque at launch and low speeds, the company said in a statement. According to Eaton, the EV transmissions feature a lightweight countershaft gearbox that boasts a range of torque capacities and electric gearshift actuation, allowing use of smaller electric motors.

Differential design and production

Eaton’s Vehicle Group offers a range of specialized differentials for EVs with performance comparable to differentials designed for traditional internal combustion engine vehicles, the company noted.

Eaton said its traction control family of differentials provide improved traction in adverse conditions such as snow and mud and improve stability while trailering. Eaton has been supplying differentials to the EV market since 2015 and offerings include automatic limited-slip, automatic locking and electronic selectable locking differentials. Performance is verified at Eaton’s Proving Ground testing complex in Marshall, Michigan, which is home to more than 600 acres of testing facilities and tracks.

“Our new ePowertrain business unit can provide our customers with an optimized, integrated EV powertrain, which will help simplify their engineering development process,” Cronin said. “We will work with our global customers to determine the ideal combination of transmission, gearing and torque solutions that best meet their EV needs.”

About the Author

FleetOwner Staff

Our Editorial Team

Kevin Jones, Editorial Director, Commercial Vehicle Group

Josh Fisher, Editor-in-Chief

Jade Brasher, Senior Editor

Jeremy Wolfe, Editor

Jenna Hume, Digital Editor

Eric Van Egeren, Art Director