Nearly 1,300 CMVs removed from service for brake violations

Brake system violations continue to plague commercial motor vehicle (CMV) fleets and truck drivers. They regularly take the top spot in roadside inspection safety violations, accounting for a significant percentage of driver out-of-service conditions.

During an unannounced brake safety day on April 27, commercial vehicle safety inspectors among 46 jurisdictions in the U.S. and Canada placed 1,290 CMVs with brake violations out of service (OOS). That’s 14.1% of the 9,132 commercial motor vehicles inspected that day.

See also: Roadside inspections: A necessary evil

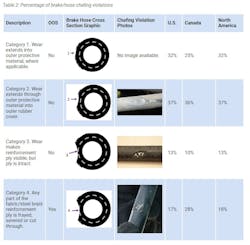

This unannounced one-day inspection and enforcement initiative, conducted by members of the Commercial Vehicle Safety Alliance (CVSA), focuses specifically on the brake systems and components on commercial motor vehicles. On Brake Safety Day, CVSA-certified inspectors conduct their usual commercial motor vehicle inspections; however, in addition, for this initiative, they also reported brake-related data to the alliance.In addition, inspectors compiled and reported brake hose/tubing violation statistics, which was the focus area for this year’s Brake Safety Day. There were 1,534 brake hose/tubing violations. CVSA asked inspectors to submit data on four categories of brake hose/tubing chafing violations (note: category 4 is the only OOS violation):

- A category 1 violation is when the wear extends into the outer protective material. Thirty-two percent of brake hose/tubing chafing violations were identified as this category.

- Category 2 is when wear extends through the outer protective material into the outer rubber cover. The largest category, 37% of brake hose/tubing chafing violations were category 2.

- In category 3, wear has made the reinforcement ply visible, but the ply remains intact. Thirteen percent of brake hose/tubing chafing violations were identified as category 3.

- In category 4, chafing has caused any part of the fabric/steel brain reinforcement ply to be frayed, severed or cut through. Eighteen percent of brake hose/tubing chafing violations were category 4.

In addition, CVSA member jurisdictions equipped with performance-based brake testers (PBBTs) participated in Brake Safety Day activities, conducting 92 inspections with PBBTs, resulting in six, or 6.5%, commercial motor vehicles being placed out of service for insufficient overall vehicle braking efficiency.

CVSA conducts two major brake-safety inspection and enforcement initiatives each year: the unannounced brake-safety campaign and the publicly announced Brake Safety Week, scheduled for scheduled for Aug. 21-27 this year.

About the Author

FleetOwner Staff

Our Editorial Team

Kevin Jones, Editorial Director, Commercial Vehicle Group

Josh Fisher, Editor-in-Chief

Jade Brasher, Senior Editor

Jeremy Wolfe, Editor

Jenna Hume, Digital Editor

Eric Van Egeren, Art Director