The heavy-duty diesel engine industry is increasingly focused on reducing greenhouse gas emissions and meeting global fuel economy targets. At the same time, businesses are sensitive to the total cost of ownership (TCO) of their fleets, so manufacturers are turning to new engine oil technology to increase efficiency and reduce costs associated with TCO. With new formulations (many barely meeting API CK-4/FA-4 specifications) coming on the market, fleets must increase their understanding of oil technology to determine which oil works best for their trucks while maximizing oil performance and efficiency.

An engine oil’s main job is to reduce friction in the engine and ensure that no two moving parts are directly in contact with each other. Oil also transfers heat away from the engine's moving parts and removes or neutralizes impurities and foreign particles that would otherwise clog filters, piston rings, and other vital components.

With the industry’s focus shifting to greater efficiency, engine oils will face increased stress and must operate under harsher conditions, for longer oil-drain intervals, and in the presence of biofuels, all without compromising protection.

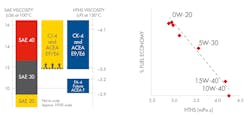

The need for improved fuel economy is driving the introduction of low-viscosity diesel engine oils. In general, lower-viscosity lubricants reduce the energy required to keep engine components in motion, reducing fuel consumption. The challenge is balancing reduced viscosity with the need to maintain engine durability. Shell Lubricants developed a fuel economy field trial program using actual trucks on the road to test low-viscosity diesel engine oils to validate engine component protection and document increased fuel efficiency during operations.

The program demonstrated that switching to low-viscosity engine oils could provide significant efficiency gains. The latest engine oil technology also offers extended drain intervals and protection in extreme operating conditions.

“It is not enough to evaluate new engine oils in the laboratory: The real test is how they protect vehicles in the real world. Shell has accumulated more than 39 million miles in testing CK-4 and FA-4 type technologies, which show excellent engine protection in the field, even at low viscosities,” said Dan Arcy, global original equipment manufacturer technical manager, heavy-duty diesel engine oil, Shell.

Choosing a premium oil that allows for longer oil drain intervals (ODI) could cut a fleet’s oil consumption considerably over the vehicle's life and reduce the stops for maintenance, hence improving uptime.

An average Class 8 truck in the U.S. travels 62,751 miles annually, and the average lifespan on the road for that truck is seven years. If the truck used an oil with a recommended oil drain interval of 35,000 miles, it would need 12 oil changes in its lifetime.

If using an oil with a higher specification, such as Shell Rotella T5 10W-30 Synthetic Blend that meets and exceeds the API CK-4 standard, the ODI would increase to around 60,000 miles, depending on the engine manufacturer and conditions. The number of oil changes drops to just seven oil changes.

Choosing a higher specification engine oil with an extended ODI also provides enhanced oxidation control to protect against oil breakdown in hot engine conditions, improved shear stability to prevent a loss of oil viscosity under severe stress, and excellent aeration control to avoid air bubbles within the oil for sustained wear protection.

The maximum time allowed between oil drains depends on the engine oil specification, the manufacturer's engine guidelines, and the vehicle’s operating conditions.

Selecting the Right Engine Oil

With new heavy-duty engine technology designed by original equipment manufacturers, the majority of today's oils are synthetics. Synthetics are made of synthesized base oil technology mixed with additives, or hybrids, made with a blend of conventional and synthetic combinations. The right oil for an application depends on the fleet vehicle operations, operating conditions, and service schedules.

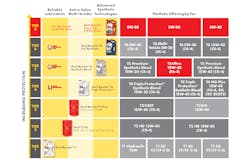

Shell’s T6, T5 and T4 options can meet a variety of different demands. For example, the Shell Rotella T6 Full Synthetic delivers better wear protection and fuel economy and offers extreme temperature protection, especially in extremely cold weather. The T6 Multi-Vehicle Full Synthetic: Extended-Drain Capable offers enhanced fuel economy capability of up to 2.8% in heavy-duty diesel applications compared to conventional SAE 15W-40 oils.

The Shell Rotella T5 Synthetic Blend Technology provides better wear protection than the previous generation of Shell Rotella T5 and offers improved fuel economy with the 10W-30 viscosity. It is ideal for those interested in lowering operating and maintenance costs. The 15W-40 viscosity option provides the benefits of a synthetic blend in this viscosity grade. The 10W-30 offers fuel economy savings of up to 2% and has up to 44% better engine wear protection than the maximum CK-4 wear requirements.

The Shell Rotella T5 Ultra Synthetic Blend Technology is for fleets with low-emission, 2017 model year and later engines designed to use an API FA-4 oil. It offers 2% fuel-economy savings and lower total operation and maintenance costs. It is also resistant to high-temperature breakdown.

The Shell Rotella T4 Triple Protection Technology is designed to protect engines under the most severe conditions. It has an average of 50% better wear protection than required by CK-4 engine tests and resists oxidation up to 50% longer than the previous generation of Shell Rotella T Triple Protection technology.

As you can see, Shell offers proven technology for optimum performance while reducing TCO.

Fleets can input their equipment specifications and operating parameters into Shell LubeMatch, an online tool, to find the right oil for their equipment.