Bollinger on the cusp of becoming ‘a true OEM’

About five years after switching focus from consumers to fleet electrification, Robert Bollinger’s company is months away from producing its first medium-duty EVs and becoming the newest entrant into the growingly competitive zero-emission fleet landscape.

Bollinger Motors is concentrating on building a solid nationwide sales and service network for its first commercial vehicle, the Bollinger B4 Chassis Cab, which the company expects to make hundreds of by year’s end.

“We’re becoming a true OEM—that’s our goal,” Bollinger, the company founder and CEO, told FleetOwner during NTEA Work Truck Week. “Once we have a true production vehicle out for sale, we’re an OEM. The amount of work to become an OEM is monumental. The team got us there.”

Bollinger’s team is growing. When he founded his namesake company in 2015, he wanted to build electric all-wheel drive trucks and SUVs. But in 2022, the company shifted its focus to medium-duty EVs. With more than 250 EV startups and emerging companies in the U.S. as of 2023, competition is fierce. A Wall Street Journal review of 43 publicly traded EV startups found that 18 were running out of cash.

Mullen provides room for Bollinger’s growth

But Bollinger Motors recently surpassed 100 employees and has at least 25 job openings at its newly renovated Oak Park, Michigan, facility. The room for growth and production came after Mullen Automotive bought a controlling interest in Bollinger in 2022, which has helped the now independent subsidiary scale up and focus on fleet vehicles.

Bollinger’s all-electric Class 4 chassis cabs are being assembled at the facility of Roush Industries in Livonia, Michigan. However, the company founder said he envisions eventually moving some production to Mullen’s Mishakawa Assembly Plant in St. Joseph County, Indiana. The company plans to begin producing its Class 5 chassis cabs in 2025.

See also: Class 3 EV Mullen Three now CARB-certified

He said the OEM hopeful has learned much working with Roush but hopes to grow large enough to move production to Mishakawa later this decade.

To grow that big, Bollinger continues to expand its dealer network, recently adding 11 more locations in Florida, Georgia, Kentucky, Maryland, Minnesota, Tennessee, and Virginia. Ten are Nacarato Truck Centers dealerships, and the Minneapolis dealer is run by Nuss Truck & Equipment. Michigan’s LaFontaine Automotive Group was the first commercial dealer to add Bollinger to its offerings.

See also: Is California ready for an electrified future?

The EV maker qualified for $40,000 in federal clean vehicle tax credits under the Inflation Reduction Act for the B4 chassis cab.

Bollinger B4 specs

Class: 4

GVWR: 15,000 lb.

Rear axle dual RWD: 10,500 lb.

Solid front axle: 6,500 lb.

Payload: 7,080 lb.

Wheelbase: 158 in.

Turn circle: 44 ft.

Cab-to-axle: 136 in.

Cab-to-box: 4 in.

Frame height: 30 in.

Frame width: 40 in.

Body length: 16-18 ft.

Horsepower: 323

Torque: 675 ft.-lb.

Range: 185 miles

AC Level 2 charge time: 9 hrs. at 19.2 kW

DC fast charge time: 2 hrs. at 110 kW

Energy and range for medium-duty fleets

Bollinger partnered with Our Next Energy to supply batteries and related components. The battery packs in the B4 can provide a 200-mile range under optimal conditions, which is more than their ideal fleet customers need in a day.

“What’s great about these trucks is that they’re in the perfect class for electrification,” Bollinger said. “Class 8—we know there are a lot of players in that game that finally might get there, but that’s a long haul. What’s great about these [medium-duty chassis] is that all of the fleets we’ve talked to—and even studies we’ve done with other third-party firms—have firmed up our suspicions on the range, which is they need anywhere from 30 miles a day to maybe 100.”

The medium-duty truck market is ripe for electrification, according to a North American Council for Freight Efficiency study on early truck electrification. The 2022 report found that 65% of medium-duty trucks on the road in California and New York could be replaced with EVs.

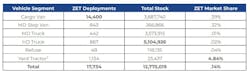

One year after that study, EVs made up just 0.33% of the nearly four million medium-duty trucks and step vans deployed across the U.S., according to a 2024 Calstart study on commercial zero-emission deployments.

Ready for upfits

Bollinger told FleetOwner that his company has worked with commercial vehicle upfitters for years to ensure that his electrified chassis is ready for the medium-duty fleet market.

“Almost every upfitter you see can put their upfit on here,” he said, pointing to the B4 chassis cab. “We’re agnostic on that front.”

He added that Bollinger wants to work with smaller and medium fleets through their dealers and upfitters to provide equipment for how the fleet is used to operating. It also talks directly with mega fleets.

“We’ll do it the way they’re used to—we aren’t asking anyone to do it our way,” he said. “We’re doing everything the traditional way, which is what fleets want. They don’t want a chassis that is difficult to upfit.”

The Bollinger chassis boasts a wider frame to accommodate a simplified and clean layout for high-voltage cables, improving maintainability and safety.

During a ride-and-drive in downtown Indianapolis, the B4’s cab-forward design and front axle showed off its tighter turning radius and easy maneuverability on urban streets.

About the Author

Josh Fisher

Editor-in-Chief

Editor-in-Chief Josh Fisher has been with FleetOwner since 2017. He covers everything from modern fleet management to operational efficiency, artificial intelligence, autonomous trucking, alternative fuels and powertrains, regulations, and emerging transportation technology. Based in Maryland, he writes the Lane Shift Ahead column about the changing North American transportation landscape.