Heat waves increase idle times, fuel costs for fleets across the U.S.

The higher the temperature, the more it costs the trucking industry.

Data from transportation operations platform Samsara backs this up. Idle data recorded by Samsara’s customers shows a direct connection between engine idling and higher-than-average temperatures.

The costs of engine idle during heat waves

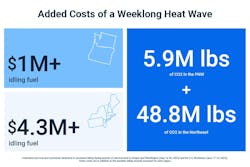

The trucking industry spends millions of dollars on engine idling, and emits millions of additional pounds of GHG into the atmosphere, according to Samsara data.

- Trucking companies in the Pacific Northwest spent an extra $1 million in fuel costs during a heat wave in August 2023.

- Also in the Pacific Northwest, trucking companies emitted 5.9 million more pounds of carbon dioxide than usual.

- Trucking companies in the Northeast spent an extra $4 million in just one week during a June 2024 heat wave.

- Northeastern trucking companies emitted 24.4 million more pounds of GHG than usual.

Without collecting this data, the increase in engine idling could go unnoticed by fleets, leading fleet owners to wonder where the excess fuel costs come from.

“Data can give fleet managers a nuanced understanding of fuel spend at scale,” Erin Post, Samsara senior data scientist, told FleetOwner. “A holistic view of average idle time, vehicle speed and location, driver efficiency scores, and more can give decision makers the information they need to make informed decisions about efficiency, safety, and sustainability as road conditions change.”

Data: Engine idle during heat waves

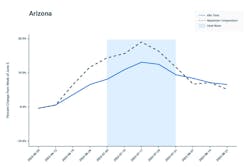

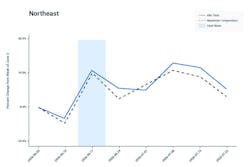

Samsara analysts examined commercial vehicle data from thousands of trips during three above-average heat waves in Oregon, Arizona, and Washington state. The team also analyzed data from nine Northeast states. The data was gathered from trucking trips between June and August 2023 and June and July 2024.

The team used daily temperature data from the National Oceanic and Atmospheric Administration to compare to the trip data.

The result?

“The proportion of time drivers spend idling increases in high heat, and there is a strong correlation between idle time and maximum temperature,” Post wrote in a report.

See also: How to keep drivers cool this summer without idling

In Arizona, temperature changes potentially explain an 84% variation in idle time, while in the Northwest, temperature accounts for 88% of idle time variation.

Data from a 2023 heat wave in the Pacific Northwest revealed idling and high temperatures moved in “almost identical unison,” according to Samsara. In June of this year in the Northeast, Samsara data also showed idling and high temperatures spiked simultaneously.

What are the costs of idling?

The more an engine idles, the more fuel it burns. Large truck operators in the Pacific Northwest spent an additional $1 million on fuel during an August heat wave last year, Samsara estimated, assuming a cost of $4 per gallon and 0.85 gallons of fuel was used per hour of idling.

During the June 2024 heat wave, Samsara estimated trucking companies in the Northeast spent more than $4.5 million on additional fuel—in just one week.

Aside from the increase in fuel usage, due to increased idle times, trucks emitted more greenhouse gases into the atmosphere. In the Pacific Northwest, commercial vehicles emitted 5.9 million pounds of carbon dioxide more than usual. Commercial vehicles in the Northeast contributed a staggering 24.4 million pounds of emissions.

See also: Uncovering the hidden costs of truck idling that eat away at your bottom line

How to mitigate engine idling in the summer heat

“Data from the Samsara platform shows that rising temperatures are strongly correlated with idling rates,” Samsara’s Post told FleetOwner. “Having a data-driven understanding of fuel efficiency and idle time is crucial for modern fleet operators who wish to control costs, increase efficiency, and operate more sustainably.”

Samsara aids fleets in lowering their engine idle times by first collecting engine idle data to help fleets set realistic targets. Summit Materials, a Samsara customer, was able to save $1.8 million per year in fuel costs after streamlining its fuel management with Samsara technology.

In addition to partnering with a telematics provider, fleets lower their engine idling during heat waves by using idle reduction technologies. The North American Council for Freight Efficiency outlines these as anti-idle engine controls, HVAC engine start/stop, truck stop electrification, and tractor solar panels, among others.

Other steps fleets can take to decrease idle include things like tractor paint, such as using a lighter color paint to decrease heat absorption. Other options include using high levels of cab insulation, powering HVAC with auxiliary power units, and more.

About the Author

Jade Brasher

Senior Editor Jade Brasher has covered vocational trucking and fleets since 2018. A graduate of The University of Alabama with a degree in journalism, Jade enjoys telling stories about the people behind the wheel and the intricate processes of the ever-evolving trucking industry.