Ancra Cargo

Ancra Cargo’s 12-in. beveled logistic O-track provides a foot of extra anchoring points to help make cargo securement easier. This machined aluminum logistic track can be used with both single-stud and double-stud O-track fittings. The beveled edges make it easy to transition the track from the floors to the walls. The track comes pre-drilled with two screw holes, and it needs to be screwed or bolted to the trailer’s walls, frames, or floorboards. The company also offers narrow-profile shoring beams that can maximize usable space for carts. The patented system optimizes beam spacing to ensure the maximum number of carts can be loaded in a safer and more secure manner so carts cannot release and roll out of the rear door when opened.

Doleco USA

The Doleco patented ConnectedDeck merges two or three adjustable, self-leveling decking beams with a formed composite panel that creates an integrated cargo platform that is easily adjustable, stores at ceiling height, and never has to be disassembled and reassembled.

Fitted with its ultra-lightweight, composite decking platform, the ConnectedDeck design enables workers to deploy and adjust an entirely decked, ready-to-load, two- or three-beamed cargo platform within 13 seconds, Doleco said. Locked at ceiling height when not in use, the unitized platform can be released with a standard dock hook or fifth-wheel pin puller. No system-specific tool is needed, eliminating the problem of missing or misplaced beam release tools.

According to Doleco, conservative calculations suggest that all things being equal, a fleet with 1,000 trailers would save $15.8 million per year by converting to its ConnectedDeck System.

Kinedyne

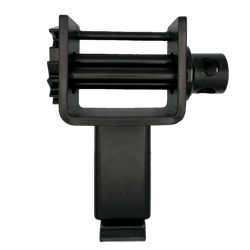

With a working load limit of 5,500 lbs., Kinedyne said its inward offset stake pocket winch is heavy-duty, versatile, and tackles tie-down troubles. This stake pocket winch can be positioned in any stake pocket quickly, ready to tie down cargo on a flatbed. The spring load hook design at the bottom of the stake pocket winch allows even weight distribution without a securement pin, according to the company.

The inward offset allows for track-mounted curtain system clearance. When the job is done, the winch can be easily removed. It's made from heat-treated steel and is coated in a sleek black powder coating. A three-bar winch mandrel design prevents the winch strap from binding.

Labelmaster

Labelmaster's weatherproof polyester strapping won't rust or stain products, is 80% lighter than steel strapping, and uses sturdy, scored seals, according to the company. Used for heavy-duty applications, such as bundling lumber or building materials and rigid palletizing, the poly-strapping offers strength, rigidity, and retained tension. Black, hand-grade polyester strapping is sold in 5/8 in. x 2,200-ft. rolls.

Logistick Inc.

Logistick’s new LogiTrack 2×3 is the "first one-way multimodal load bar system," according to the company. It is designed to secure lightweight loads with a standard 96-in. 2×3. It is manufactured from high-performance recycled plastic and developed for use in trailers and containers with smooth or corrugated walls. Vertical track installation maximizes performance and adhesion in tight areas, like near the doors or peaks and valleys of containers. The pocket and beam are oriented horizontally to maximize strength and holding power. It features engineered material and Logistick’s thickest, strongest tape. No tools are required for this load bar system.

Sortimo of North America

Sortimo’s telescopic ProSafe restraint pole is said to make form-fitting load securing simpler and more flexible. The telescopic function enables the pole to be adjusted to the required length. The same pole can be used horizontally or vertically with larger vehicles. With its large adjustment range of up to 500 mm, the restraint pole can be transferred when changing vehicles. The eccentric shape of the restraint pole ensures that the distance between the two poles is reduced should any loads between the two poles move. The telescopic restraint poles feature a plastic protective sleeve to protect cargo. The two integrated ProClick interfaces provide additional storage options for smaller tools.

See also: Product Spotlight: Vehicle lighting

Tramec-Sloan, a division of Fleet Engineers

Tramec-Sloan's Save-A-Load hydraulic cargo bars can be used to secure everything from small boxes to large loose cargo and bulky items. Suitable for use on commercial trucks and trailers, it can be mounted horizontally or vertically and can be used as a cargo divider. Save-A-Load's integrated hydraulic pump maintains a constant pressure to keep cargo in place without falling, the company said. When ready to unload, the bar is easily removed with the press of a button. The bar holds its position even when the trailer walls flex. An internal pressure relief valve prevents over-compressing to minimize trailer/body wall damage, and a pressurized spring holds the bar in place while adding multiple bars/hoops on the same load.

Ty-Gard International Inc.

Walnut Industries' Ty-Gard DS flexible restraint system is designed to protect cargo for multimodal transit. Engineered in a 24-in.-wide flexible band, the Ty-Gard DS is laminated with a high-strength, pressure-sensitive acrylic adhesive, offering high-shear strength on container walls. It peels and removes easily without leaving surface residue. According to the company, not only is Ty-Gard DS economical and easy to install, it does not require anchor points, wood floors, or nails; does not restrict air flow; prevents damage; and reduces securing costs. It's available in four packs and reverse band formats.

U.S. Cargo Control

U.S. Cargo Control's 2 in. x 30 ft. reverse-action ratchet strap tightens when pulled down, reducing the effort required to achieve a secure hold. An additional gear in the ratchet's construction allows the handle to be pulled down using arms and body weight, eliminating strain to the back, neck, and shoulders, reducing injuries, promoting better posture, and ensuring stable footing. The ratchet provides more gear clicks when the handle is in motion for improved tension control and can achieve nearly twice the tension on the strap with equal or less effort, according to the company. A convenient side knob allows the mandrel to spin to eliminate strap slack, streamlining webbing take-up and release. The straps are labeled to meet or exceed all FMCSA/DOT requirements.

US Tarp

US Tarp’s Stationary LT Gantry Tarp System, the newest entry in the Waste Warrior line of gantries, is designed to provide a reliable and efficient solution for Class 3 and Class 4 trucks. The 4-inch cab-to-hoist clearance removes install limits by allowing the hoist system to be mounted without custom-frame fabrication or extending the frame rails.

The heavy-gauge tubing design minimizes movement and provides maximum stability, according to US Tarp. The Stationary LT is suitable for refuse, recycling, construction, and landscaping applications. Available with aluminum or steel arm kits, the Stationary LT comes in pull style or motorized options, depending on the application. Designed for ease of use, the system has pre-assembled housing that saves time during installation, and the system ships via the easily stored US Tarp OneBox.

About the Author

Jenna Hume

Digital Editor

Digital Content Specialist Jenna Hume joined FleetOwner in November 2023 and previously worked as a writer in the gaming industry. She has a Bachelor of Fine Arts degree in creative writing from Truman State University and a master of Fine Arts degree in writing from Lindenwood University. She is currently based in Missouri.