AACHEN, GERMANY. Looking to the “digital future” of transportation, ZF Friedrichshafen AG offered international media gathered here a preview of the ZF Innovation Truck 2016, a system designed to recognize its surroundings in three dimensions using sensor fusion, then to process the data and to directly execute the resulting commands using advanced “mechatronics,” including electrified drive and steering systems.

The company bills the ZF Innovation Truck as the first commercial vehicle to feature its assist systems that have been implemented successfully for cars, and it will be the centerpiece of ZF’s exhibit at this fall’s IAA Commercial Vehicles show in Hannover.

“We need to release the driver from the difficult tasks so that they can drive a longer period on the highway, so it’s really value creation,” said ZF CEO Dr. Stefan Sommer.

Key elements of the platform include the Evasive Maneuver Assist (EMA) developed in cooperation with WABCO, which automatically steers tractor-trailers around hazardous areas safely and helps to prevent rear-end collisions. Similarly, the Highway Driving Assist (HDA) actively keeps the vehicle in its lane and at an appropriate, safe distance from the vehicle in front.

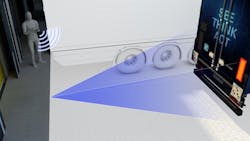

The ZF Innovation Truck also has the capability to improve safety and efficiency in loading zones, automatically maneuvering into the specified dock. With this autonomous maneuvering function, SafeRange, the platform demonstrates how sensors, intelligent electronics and mechatronic systems can optimize processes at transport hubs by networking vehicle and depot.

Based on stationary camera data, the concept vehicle maneuvers automatically to the loading dock.

See the SafeRange demonstration video

"With the Innovation Truck 2016, we are aiming to deliver a highly practical concept which optimizes workflows within the logistics industry and factors in the cost considerations of transport companies,” said Winfried Gründler, head of Truck & Van Driveline Technology in ZF’s Commercial Vehicle Technology Division.

The development began with a ZF concept unveiled in 2014, which allowed a driverless, long heavy-duty truck to be easily maneuvered using a tablet. The Innovation Truck 2016 adopts a new approach. The system’s eyes and brain do not necessarily have to be in the vehicle.

Stationary cameras on the loading dock detect the maneuvering truck which is simply tagged with a target on the rear of the trailer. A computer installed at the depot calculates the trajectory and transmits the data via Wi-Fi to the ZF Openmatics telematics system in the truck. The vehicle control system then takea over, using ZF TRW's active electric power steering, ReAX, and the TraXon Hybrid automatic transmission system to steer the truck to the loading dock electrically and emission-free.

The TraXon Hybrid allows the short distances in the depot to be driven in electric mode. The electric motor also provides very precise longitudinal acceleration. The steering has been designed so that full servo assistance is also available in electric mode, i.e. with the engine switched off.

In an added development to the 2014 ZF concept, SafeRange relieves the person operating the system from carrying out the remote maneuver; the operator simply begins the operation using the tablet and keeps the function active until the vehicle has maneuvered into position. The truck will only keep moving if the operator constantly gives the appropriate command on the tablet. As soon as the operator takes their hand off the tablet, the truck stops.

Additionally, pedestrian detection automatically interrupts the maneuvering operation whenever someone is between the trailer and loading dock.