Key takeaways:

- Tariffs have decreased new orders and increased material costs, harming U.S. manufacturing competitiveness.

- Trucking demand and capacity is back to pre-COVID levels, while the number of carriers is up 40%.

- The automotive industry, dependent on imports, faces production constraints that could increase inflation as demand remains high.

A freight market beginning to find its footing is back on shaky ground, given the wide-ranging business anxiety that followed President Trump’s tariff plan revealed April 2.

“If we would have done this call about two months ago, it would have been much more encouraging,” Jason Miller, Eli Broad professor of supply chain management at Michigan State, said early in his Stifel freight forecast presentation April 4. “We get at least two months. If by June 1, this is all behind us, it should be a decent back half of the year.”

Miller highlighted the critical role of U.S. manufacturing as a driver of freight demand, a connection often overshadowed by a focus on imports. While 2024 saw weak trucking market activity despite strong import volumes, early 2025 initially presented a more encouraging outlook.

However, recent data revealed a concerning trend: New order indices have turned sharply negative, to go along with a strong upward momentum for prices paid for materials. This unusual combination, where new orders decline while prices increase, signals a difficult environment for manufacturers.

“It's odd for new orders to go down and prices to go up,” Miller said. “This is not the combination that we want to be seeing.”

A key factor contributing to this pricing pressure is the increasing cost of raw materials like aluminum and steel in the U.S. compared to overseas markets, a disparity exacerbated by existing tariffs, Miller explained. This cost disadvantage threatens the competitiveness of U.S. manufacturers in both domestic and export markets.

See also: How do you expect tariffs to impact your operations?

Trucking measures

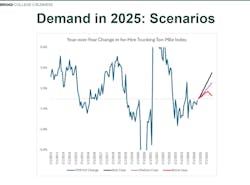

Looking at the current state of the freight market, Miller’s presentation touched on several metrics.

The Trucking Ton-Mile Index, co-authored by Miller, showed recent volatility, partly due to unusual seasonal patterns and weather events. Analyzing trucking payroll data, Miller suggested that the post-COVID gains in trucking capacity have dissipated.

“Effectively, trucking freight demand is around 2019 levels, maybe slightly higher,” Miller said. “Trucking capacity is around 2019 levels, maybe slightly higher, give or take, but we've given up all of our post-COVID gains.”

Of note: The number of active trucking firms has significantly increased.

“We've got 20,000 additional [carriers] off of a base of 45,000 so that's almost a 40% increase in the number of firms—but capacity in total hasn't changed,” Miller said. “So what that means is capacity is more dispersed today than it was before the pandemic. From a shipper standpoint, that means the role of the broker is even more important today to access that capacity pool.”

As for rates, the dry van truckload market experienced a recent downturn in spot rates after an initial period of optimism, Miller reported.

“If you go back two-and-a-half months ago, the dry van space was humming. Rates were up to about $2.15 a mile; fuel was down,” he said. “Folks were getting excited; predictions were the market was ready to turn. Then February hit, and then March hit, and those rates have dropped off.”

While contract rates showed some year-over-year increase, the downward pressure on spot rates is likely to offset this momentum, he noted.

Automotive imports

A significant portion of the presentation focused on the motor vehicle sector, a key area directly impacted by the tariffs.

The U.S. currently imports about 40% of its automobiles and parts, Miller explained. Current capacity utilization rates in domestic auto assembly and parts plants, at around 80%, indicate limited ability to compensate for a sudden drop in imports. Establishing new domestic auto production capacity is a long-term endeavor, requiring several years for greenfield construction and production to start.

“The translation of this, folks, is there's no way this is not inflationary,” Miller said. “You just cannot get around this.”

Additionally, recent data revealed record sales of light trucks and utility vehicles, suggesting a potential pull-forward of demand. While dealer inventories had been relatively high, they are expected to decrease significantly following these strong sales. Despite resolved supply chain issues in the auto sector, dealer margins have returned to pre-pandemic levels, limiting their capacity to absorb tariff costs, Miller noted. Domestic vehicle assemblies remain below 2018-2019 levels, and recent production adjustments by major automakers in response to potential tariff impacts signal further uncertainty.

“Auto parts, right now coming in under USMCA, are exempt—until Customs and Border Protection figures out a way to factor out the U.S. value added,” Miller said. “That is the key thing right now. How are they going to keep track of this? I don't know.”

‘Absolutely nuts’

The tariffs announcement has injected significant uncertainty into the economic outlook. Miller emphasized the potential for significant inflationary effects and retaliatory tariffs from other countries, already evidenced by China's announced 34% tariff on U.S. goods.

“I wish I had something more scientific than this, but the last couple of days have just been absolutely nuts,” Miller said, echoing the title slide of for the tariffs portion of the presentation.“The reciprocal tariff was completely a fabricated number. It was our trade deficit in goods divided by our imports from that country. So just to be very clear, those numbers are made up.”

Contradictory statements from the White House are adding to the confusion and uncertainty.

“You have Peter Navarro [senior trade and manufacturing adviser to President Trump] saying ‘no negotiation.’ Then you have Trump saying ‘negotiation,’” Miller said. “We have to have clarity. I don't care what political side of the spectrum you're on; we have to have clarity. What is the goal of the tariffs? If they're a negotiating tool, they're not going to bring back manufacturing jobs.”

The China trade issue is 'particularly problematic'

The U.S. and European countries had already been putting tariffs in place to combat overproduction from China, and the Trump tariff plan is now putting the U.S. in an adversarial relationship with traditional trading partners and allies.

“The irony is China has benefited tremendously from this because they now look like a stable country," Miller said. "We missed the golden window to actually combat China and instead destroyed our standing in the world from that standpoint.”

The tariffs, if sustained, could lead to a loss of export market share for U.S. manufacturers as other countries seek more stable trading partners, Miller added. He also highlighted the potential negative impact of the proposed China ship fee rule, which could severely disrupt U.S. exports.

While current data on auto loan and credit card delinquencies do not yet signal an imminent consumer lockdown, and a recent jobs report beat expectations, Miller cautioned that the tariff shock significantly increases the risk of a recession if these policies remain in place for an extended period and trigger further retaliatory measures. The Federal Reserve is unlikely to lower interest rates until it is convinced the tariffs are not inflationary, potentially delaying any monetary easing.

“Until the jobs market starts to really look bad, there's no reason to think that the overall economy is yet set on coming falling into a recession,” he said

The long-term consequences for U.S. manufacturing competitiveness and global trade relationships remain highly uncertain, Miller concluded.

“If we do it quickly, I think we can unwind it,” Miller concluded. “If we don't, then I'm very discouraged. If these higher rates stay in place longer than three months, I don't see how we don't end up in a recession within six months.”

About the Author

Kevin Jones

Editor

Kevin has served as editor-in-chief of Trailer/Body Builders magazine since 2017—just the third editor in the magazine’s 60 years. He is also editorial director for Endeavor Business Media’s Commercial Vehicle group, which includes FleetOwner, Bulk Transporter, Refrigerated Transporter, American Trucker, and Fleet Maintenance magazines and websites.

Working from Beaufort, S.C., Kevin has covered trucking and manufacturing for nearly 20 years. His writing and commentary about the trucking industry and, previously, business and government, has been recognized with numerous state, regional, and national journalism awards.