Wabash expands EcoNex production

Wabash is expanding production of EcoNex Technology to address equipment challenges faced by refrigerated carriers, including thermal efficiency, strength, weight, and asset life.

As part of the expansion, Wabash is investing an additional $20 million at its 53-acre facility in Little Falls, Minnesota, to boost manufacturing capacity, and adding more than 200 jobs by the end of 2023, the company said.

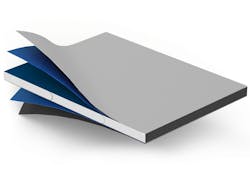

EcoNex is Wabash’s proprietary, next-generation molded structural composite that utilizes environmentally conscious materials aimed at reducing greenhouse gas emissions and dependency on non-renewable energy. A refrigerated trailer with EcoNex is estimated to save up to 13.5 metric tons of CO2e per year, compared to Wabash’s former ArcticLite refrigerated trailer made with conventional materials, Wabash maintained.

“What’s more, we think EcoNex has applications beyond our core markets because of its superior thermal capability, weight, and strength. Our investment to expand EcoNex capacity, which we discussed at our May investor meeting, is intended to serve our trailer and truck body customers while we scale EcoNex in adjacent industries.”

EcoNex boasts greater thermal capability while being lighter weight, and Wabash says the technology “substantially reduces” corrosion and extends asset life. This is a sustainability advantage that is additive to customers’ environmental objectives. Wabash has demonstrated the value-add properties of EcoNex with more than 30 million miles of use.

“Whether we are transporting frozen vegetables in the heat of summer or fresh fruit in the cold of winter, EcoNex Technology assures the temperatures inside the trailers are consistent,” said Ken Johnson, CEO at Leonard’s Express.