ATLANTA — As Bendix makes way for increased brake production, the commercial vehicle safety systems company is planning for the next generation of automated safety technology for today’s fleets.

The popularity of the ADB22X — Bendix has now produced more than 3 million of the air disc brakes — was a major factor in the decision to add to the Bendix Spicer Foundation Brake wheel-end manufacturing facility in Kentucky, executives said during an expansive Bendix press conference at the North American Commercial Vehicle Show (NACV) this week.

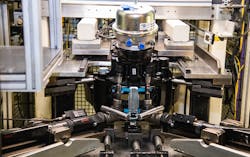

The 130,000-sq.-ft. addition will add a third ADB production line, four ADB caliper machining centers, and expanded engineering test capability. The company broke ground in Bowling Green this September.

Bendix didn’t stop with brakes. The safety systems company shared a number of product updates and announcements at NACV, including a focus on automation.

The next-generation of Wingman Fusion’s Lane Centering will integrate the camera and steering systems to help keep a vehicle centered along a projected path of travel, while Lane Change Assist will monitor the sides of a tractor-trailer, relative to the lane markings. Side radar will also enable Pedestrian/Cyclist Alerts and feedback.

Highway Assist will engage when Fusion’s active cruise control with braking is set: The vehicle will not only maintain a distance with the forward vehicle – increasing safety – but will also track to near center, automatically, and follow to a defined trajectory to assist the truck and trailer to stay within the intended lane. The driver will need to have their hands on the wheel, but the system will reduce driver fatigue associated with micro-adjustments needed during normal driving activity. It is especially useful in light to moderate traffic where cut-ins and road curvatures can wear a driver down over a long day’s work.

Building on Highway Assist, Traffic Jam Assist further helps the driver when traffic becomes heavy, as the system will help the driver steer and brake at low speeds when backed-up traffic causes slowdowns. Upcoming versions of Fusion will retain the capabilities of the system’s earlier versions: Stationary object alerts, over-speed alerts and intervention, lane departure warning, and prioritizing alerts to help reduce driver distraction.

Fusion can also deliver enhanced rear-end collision mitigation and stationary vehicle braking, along with multilane automatic emergency braking, highway departure braking, ACB (Active Cruise with Braking) Stop & Driver Go, and ACB Auto-Resume. Fusion has the capacity to provide full braking power on the tractor, which combined with earlier object detection – can help reduce a vehicle’s speed by as much as 50 miles per hour when encountering stationary and slower-moving vehicles. Lane Keeping Assist technology means that if a driver intends to change lanes while a vehicle is detected, Fusion will be able to deliver haptic feedback and steering resistance. Because it is built on the Bendix ESP Electronic Stability Program full-stability system, Bendix Wingman Fusion also helps drivers avoid additional crash situations, including rollovers and loss-of-control. Event-based data – including video – can be wirelessly transmitted for driver coaching and analysis by fleet safety personnel.

Air disc brake technology improvements

Since 2014, North American market share for air disc brakes has doubled to more than 25%, with the Bendix ADB22X accounting for about 80% of that share, according to the company.

As wheel-end-technology adoption grows, the Bendix continues to refine the ADB22X air disc brake with the Bendix Splined Disc. The company is also introducing pad-wear sensing on all versions of the ADB22X, the company announced at NACV.

“There are plenty of reasons why we’ve put more than 3 million Bendix air disc brakes on the road; and next year, we expect to see ADBs on nearly 35% of North American Class 6-8 wheel-ends,” said Keith McComsey, director of marketing and customer solutions for Wheel-End at Bendix Spicer Foundation Brake. “Included in those reasons are safety, stopping distance, and reliability, of course, along with increased uptime — but we think a lot of our success is also due to the constant incremental efforts to optimize the ADB22X since we started producing it almost 15 years ago.”

In early 2019, Bendix implemented improvements to the ADB22X that included a new adjustment mechanism to increase robustness against vibration, while improving the running clearance between the friction and rotor.

The changes earlier this year also included coupling the ADB22X with Bendix’s long-life air disc brake friction, the Bendix BX276 air disc brake pad. The BX276 pad, which includes an additional 2 millimeters of friction compared with its predecessor (the BX275), add 8% more wearable volume and a 40% reduction in wear rate at higher temperatures than its predecessor.

The new ADB brake pad wear-sensing is available for all versions of the ADB22X as new equipment from select-truck and -trailer manufacturers, as well as in aftermarket service kits. The technology reduces maintenance costs by alerting fleets, via telematics, when ADB pads are nearing replacement. This eliminates the need for technicians to constantly measure friction, thereby allowing fleets to optimize friction replacement schedules. It also helps fleets protect costly ADB components, such as rotors, from damage by worn out pads.

To help fleets see potential returns on investment with ADB, there is a cost calculator at ValuebyBendix.com.