Lightweighting technologies offer a significant chance to reduce fuel usage and boost payload capacity for fleets, but few fleets are actually taking full advantage of the opportunities, according to a new Confidence Report from Trucking Efficiency.

The report said that, due to emissions regulations, fuel economy features and driver amenities, tractors have gained about 1,000 lbs. of weight over the past decade. That weight, though, could be easily offset with lightweight technologies. Trucking Efficiency’s latest Confidence Report on lightweighting said that about 2,000 lbs. of weight can be cut from a truck with a “limited degree of lightweighting, while more aggressive investment can yield around 4,000 lbs. of savings – at which point 1 in every 11 trucks that gross out can be taken off the road for a given amount of cargo.”

The time, the report said, is now for fleets to start adopting lightweight technologies, especially as shippers are demanding more efficiency and freight is becoming denser, leading to more vehicles maxing out at 80,000 lbs.

Trucking Efficiency is a joint effort of the Carbon War Room and the North American Council for Freight Efficiency.

Lightweighting also has an impact on the growing driver shortage, the report noted. With more freight and more dense freight, fleets will have two options: add trucks or cut vehicle weight. The report is clear which option Trucking Efficiency believes is best.

“A new truck costs around $120,000 up front, and an additional $1.68 per mile to operate. With trucks driving [about] 100,000 mi. or more annually, investing in lightweighting such that a single vehicle can be kept off the road while still moving the required amount of freight would save a fleet nearly a million dollars over five years. And at current industry averages of just under 6 mpg, one fewer truck means reduced CO2 emissions of nearly 380,000 lbs. per year,” the report said.

In the report, Trucking Efficiency measures the value of lightweighting technologies in “dollar of upfront cost per pound of weight saved.”

Click to see Fleet Owner's report on the new truck models for 2016

Few fleets willing to pay for technology

According to the report, category 1 fleets (primarily bulk operations operating at max weight during at least some portion of their route) have already invested heavily in lightweighting initiatives and are willing to pay for such technologies. A cost of between $6 and $11 per pound of weight saved is justified by these fleets, the report said, noting that a technology that saves 500 lbs. might be worth an upfront cost of $5,500 for these fleets.

Conversely, those fleets in category 2 (trucks loaded to max weight a minimum amount of time) and category 3 (dry vans that rarely ever reach max weight) are less willing to spend on lightweighting technologies. On average, the group said reefer or certain dry van operators running dedicated routes are willing to pay between $2 and $5 while general dry van freight operators less than $2 for every pound saved.

Noting that category 2 and 3 trucks represent about 98% of all trucks on the road, Trucking Efficiency said plenty of increased efficiency is possible, resulting in between 0.5% and 0.6% of fuel saved per 1,000 lbs. of weight reduction.

“However, the upfront costs to remove the nearly 4,000 lbs. off a tractor and trailer required to reach the 1–2% efficiency gain considered acceptable for many other technologies is so high that it does not offer an attractive payback from fuel savings alone,” the report noted. “But with an 80,000-lb. legal maximum weight for a truck plus cargo to travel down our roads, theoretically every pound shaved off the vehicle’s weight could be recouped as freight.”

Breaking down the true costs

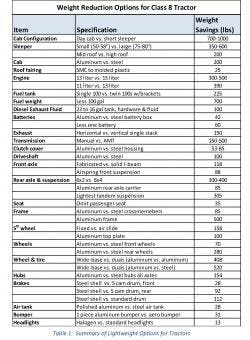

The group breaks down lightweighting technologies into 3 price categories for tractors: no cost - generally right-sizing components such as using shorter cabs, smaller engines, fewer batteries, etc.; some cost – things like increased use of aluminum in hubs, air tanks, battery boxes and molded plastics fairings; and more cost – aluminum frame and wheels, composite brake drums and the use of carbon fiber.

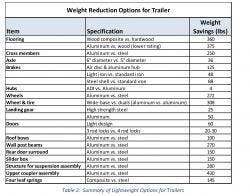

It does the same breakdown for trailers.

There are concerns about lightweighting, Trucking Efficiency pointed out, including higher upfront costs with more aggressive technologies and a potential impact on resale value and maintenance costs.

“Some lightweighting options have a negative impact on the residual cost or resale value of a truck at present. Some lightweighting options also entail higher maintenance costs,” it said.

Among areas where lightweighting is possible, the report cited powertrains, drive shafts, front axles and suspensions, rear axles and suspensions, wheel ends, wheels and tires, frame and chassis, and fifth wheels.

Using the right materials, the group said a Class 8 day cab could weigh less than 14,000 lbs. and a sleeper 15,000 lbs. It produced the following table to indicate lightweighting options:

Each area also has drawbacks. For instance, while right-sizing engines to 13L or even 11L might reduce weight and improve fuel economy, the report noted that buyers of tractors on the used market, in addition to many drivers, still prefer 15L engines. As a result, a vehicle may have less value on the resale market.

Trailer lightweighting can be addressed through lightweight brakes, hubs, and suspensions, which could deliver savings of 600 to 700 lbs., the report said. Other areas include flooring, tires and wheels and even smaller fuel tanks for refrigeration units.

The report suggested two “technology packages” for lightweighting. Package one, “mild lightweighting,” would cut about 2,000 lbs. from a tractor-trailer combination. It would include smaller fuel tanks, wide base tires and wheels, horizontal exhaust among the tractor spec choices and aluminum and other lightweight components on the trailer.

A more aggressive lightweighting package would save about 4,000 lbs. on the combo and would add a smaller engine, shorter sleeper, and aluminum to the tractor and wide-base tires and wheels to the trailer.

While the report makes it seem like all fleets should immediately adopt these technologies, it does point out a number of challenges facing fleets. From higher upfront costs; higher maintenance costs; potential drops in resale value; the cost to perform validation testing and the general nature of fleet operations, where no two vehicles seem to perform the exact same functions or travel the exact same routes under the same conditions make it hard to conduct cost comparisons.

On the horizon

Interestingly, report authors asked respondents to identify future technologies, both near-term and in the future. In the near term (within the next couple of years), the choices were:

- Plastic hoods 25-30% lighter than current models

- High strength steel frame – 200-300 lb, savings

- Composite brake drums, rear – 200 lb. savings

- Composite brake drums, front – 85 lb. savings

- Aluminum frame – 500 pound savings (note: aluminum frames are available today, but the report said more robust designs are needed to make them viable)

Future technologies include:

- Carbon fiber cab & trailer body – 5,000+ lb. savings

- Carbon fiber prop shaft – 50% lighter than current models

- Gas turbine or OPOC engine – 1,100 lb. savings

The report concludes with several other benefits of lightweighting, including fuel economy improvements and driver retention.