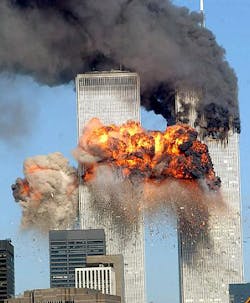

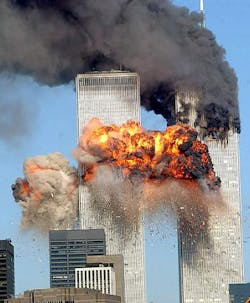

Concerns over terrorism rightly haven’t declined – indeed, there’s ongoing debate as to what kinds of terrorists we need to worry about the most.

Neither is concern abating over how the business community should prepare itself to deal with another such horrific event – indeed, how businesses large and small should step up efforts to develop emergency plans in order to deal with any type of disaster, be it a terrorist attack or force of nature.

In fact, one of the reasons the death toll at the World Trade Center after the Sept. 11 attacks wasn’t higher is due to the lessons learned from the first attack on the twin towers in 1993 – with corporate security executives endeavoring to make sure employees implicitly understood the need to evacuate the buildings in case of an emergency.

Those lessons thus saved probably hundreds, if not thousands, of lives eight years later during the second awful “day of infamy” in our nation’s history.

For that reason, the recent effort by office supply giant Staples and the National Safety Council (NSC) during to provide a variety of tips to help small businesses prepare for emergencies is worth a look. Staples’ brand new Safety Research Center on its website provides useful information help small businesses prepare for both run-of-the-mill safety issues as well as big-time emergencies.

Think this is just re-stating the obvious? That the business community doesn’t need such tools? Well, a recent survey Staples conducted through a third-party research company with 208 office managers and 204 office workers at small companies with under 50 employees back in May indicates otherwise.

Check out some of the results:

- Nearly 70% of managers in the Staples survey said their company has an emergency communication plan; yet nearly half of the office workers are either unsure if a plan exists or say their company doesn’t have a plan.

- Only 50% of office workers said they participate in safety drills only once every few years or never. Only 19% of office workers think their company is prepared for a major medical emergency.

- Managers were almost 50% more likely than non–managers to be able to locate their company’s safety-related supplies such as defibrillators, eye wash, dust masks, etc.

- When it comes to fire, more than 70% of both managers and office workers felt their company was somewhat or very prepared.

- When it comes to flooding only 50% of employees felt their company was adequately prepared. This is a particularly worrisome statistic, as the National Weather Service forecast office notes that flooding causes more damage in the U.S. than any other severe weather-related event: an average of $4.6 billion a year.

- While 56% of managers said they were either very prepared or somewhat prepared in case of a hazardous material exposure, only 23% of office workers said they would know what to do in that circumstance.

“The Federal government issues around 70 disaster declarations annually, which means hundreds of businesses, communities and families face unexpected disruption and significant hardship each year,” said Janet Froetscher, the group’s president and CEO. “Good preparation includes designing an emergency action plan to make sure you have the proper emergency supplies and safety products on hand.”

Indeed, an effective safety and health program can save $4 to $6 for every $1 invested, according to data provided by the U.S. Occupational Safety and Health Administration (OSHA). That’s another reason why NSC is offering some general tips for businesses to mull over:

- Make an emergency plan. Small businesses should post an emergency evacuation plan and emergency action plan. The plan should include: emergency contact numbers, local medical facility locations and contact numbers, who in the workplace is trained in first aid, how to ensure that personnel is accounted for and in a safe location, etc.

- Build an emergency kit. An emergency kitincludes the basics for survival, such as flashlights, extra batteries, battery powered or hand crank radio, dust masks and first aid kits. Keep copies of important records stored in a waterproof, fire proof container. These records can include building plans, insurance policies, employee contact information, bank account records and other important documents.

- Back up your data. Have back-up plansto ensure crucial data won’t be lost during a power outage or the next storm. Only half of office managers in the Staples.com survey said their company had back-up plans in place.

- Practice. Good preparation means conducting regular safety drills. However, the Staples.com survey found that 50% of office workers participate in drills only once every few years or never. In the case of a hazardous material exposure or a major medical emergency, less than a quarter (23 % and 19%, respectively) of office workers said they would know what to do in that circumstance.

- Get involved. Consider taking a first aid course or emergency response training.

Back in April, Gregory Jaczko (at right), the outgoing chairman of the U.S. Nuclear Regulatory Commission (NRC), talked about that very issue and why it should worry not just those operating nuclear plants and other high-profile facilities that are home to hazardous materials.

“The attacks on September 11 prompted extensive changes to our security requirements and one of the biggest changes in this design basis threat has been in the area of cyber security,” he explained.

“Malicious cyber activity has proliferated in the past decade, making it a clear and credible threat,” Jaczko added. “And it has caused a significant shift for an agency traditionally focused on physical security, and on the safety of reactors and other facilities built in a far less automated age. It has become clear how safety and security are intertwined when we look at issues involving the reliability and vulnerability of the offsite electrical grid, as well as digital safety systems, to a cyber attack.”

He pointed out that, several years ago, cyber weapons against critical infrastructure were considered a future threat, and were estimated to be perhaps a decade away.

“Then in 2010, the Stuxnet computer malware was discovered,” Jaczko said. “In the case of a cyber weapon such as Stuxnet, this event serves as a proof of concept – or a template – for future attacks. And we have already seen some proliferation of Stuxnet-like programs since that time. In the future, security threats may not involve just a direct attack using guns and vehicle bombs, but also indirect attacks involving malicious computer programs. Since the threat timeline is moving faster all the time, we have to ensure that we never become complacent – we must always be forward-looking.”

Indeed, keeping our collective eyes open and scanning for the next threat is one of the many legacies of Sept. 11 that will be with us far into the future.