Electric last-mile delivery could save industry $540M this season

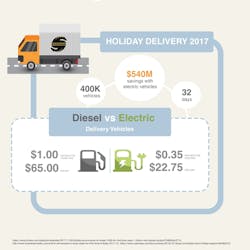

In the 32 days between Black Friday and Christmas, 400,000 delivery vehicles will deliver more than 30 million packages a day across the U.S.

With all that driving and delivering going on across the country, Ohio-based Workhorse Group says delivery fleets could save a lot of money on last-mile delivery with electric-powered trucks like the vehicles the OEM produces.

Holiday e-commerce spending is expected to surpass $100 billion this year. And 2017 is the first year that online sales are expected to exceed in-stores sales; as 70% of all homeowners expect to receive a package this holiday season.

Workhorse asks: How will roughly 1 billion packages be delivered in a cost-effective way?

Last-mile delivery adds up to almost 50% of the delivery cost, according to the OEM, which has produced some sharp infographics to highlight how going electric could keep delivery costs down.

According to Workhorse, diesel vehicles cost $1 per mile, which adds up to $65.00 per day; but electric vehicles cost $0.35 per mile, amounting to about a third of the cost at $22.75 per day.

If all 400,000 package-delivery vehicles were using battery-powered delivery instead of diesel, it would amount to $540 million in last-mile-delivery savings.

Large U.S. companies such as FedEx, Frito Lay, UPS, and Ryder have already added electric Workhorse vehicles to their fleets.

As a busy 2017 nears its end, the OEM is celebrating its work “to innovate the transportation space using electric fleet delivery vehicles to transform last mile delivery.”

In 2017 Workhorse:

- Unveiled the N-GEN ultra low delivery platform, electric delivery van;

- Unveiled the first all electric, plug-in, extended range pickup truck;

- Unveiled the SureFly personal passenger drone;

- Partnered with UPS for drone delivery testing;

- Was named a finalist for the pending USPS $6 billion postal truck contract.

About the Author

Josh Fisher

Editor-in-Chief

Editor-in-Chief Josh Fisher has been with FleetOwner since 2017. He covers everything from modern fleet management to operational efficiency, artificial intelligence, autonomous trucking, alternative fuels and powertrains, regulations, and emerging transportation technology. Based in Maryland, he writes the Lane Shift Ahead column about the changing North American transportation landscape.