Trailer “drops” that happen when a trailer is not properly secured to a tractor’s fifth wheel is a costly and dangerous problem in trucking that’s largely underreported, according to Mark Molitor, vice president of engineering for the Americas for SAF-Holland.

He noted that one TL fleet operating 10,000 trailers SAF-Holland worked with – “a fleet with a great safety record,” Molitor stressed – suffered 200 trailer drops a year.

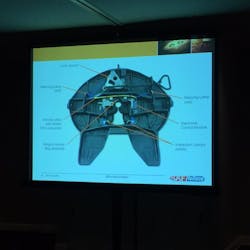

To combat that problem, SAF-Holland designed what it calls the “ELI-te” electronic lock indicator system, which uses LED lights to indicate for drivers whether the trailer kingpin is properly secured within the fifth wheel locking mechanism or not.

To be offered as either an integrated option on its FW35 fifth wheel product line or as an aftermarket retrofit kit starting next year, Bryan Redeker, product manager for fifth wheels at SAF-Holland, added that this “visual” indicator system offers reliable operation in poor weather conditions and does not require extensive experience or training to use properly.

“Cold winter weather or hot conditions can make it difficult to recognize a trailer locking issue before it becomes a problem,” Redeker explained during a media event this week in St. Louis, MO. “A dropped trailer costs thousands or more to a fleet so we wanted to develop a way to assist drivers with trailer locking inspections so they don’t have to rely solely on a flashlight and what their eyes see.”

He noted that when a trailer kingpin is properly coupled to an ELI-te equipped fifth wheel, four “high-intensity” white LED lights mounted within the fifth wheel automatically illuminate the lock jaws.

"This assists drivers with the visual safety inspection process by directing their attention to the critical connection between the lock jaws and kingpin,” Redeker pointed out.

But if a coupling problem is detected, daytime-visible red LED lights will begin flashing from both sides of the fifth wheel to alert drivers that the vehicle is not ready for motion.

“The lights make it easy for drivers to positively confirm that they have coupled correctly, and warn them if they have not,” added Molitor. “It’s a new generation of safety.”

He pointed out that one reason the ELI-te indicator lights are mounted to the fifth wheel and not located inside the tractor on the dashboard is that “dashboard space is limited” and to ensure that drivers still get out of the truck to conduct a physical inspection.

Redeker noted that the sealed one-piece ELI-te harness does require a 12 volt power hook up to the tractor but that no connection is made between the device and the trailer.

Bill Hicks, director of product planning for the Americas at SAF-Holland, said the company is in production with the ELI-te system right now and is working through the truck OEMs to get it listed in their databooks hopefully within the first quarter of 2017.

He added that SAF-Holland’s aftermarket team is also developing an ELI-te retrofit kit that should be available soon. However, pricing for either the factory-installed option or the retrofit package is not available yet, Hicks said.

A few other notes regarding the ELI-te system:

- The system’s sensors and shatter-proof lamp modules are combined with a sealed, one-piece electrical harness.

- That harness features a one-connector assembly that requires only a low-12 volt current connection to the vehicle electrical power.

- For converter dolly applications, the electrical connection is designed to be compatible with antilock brake system (ABS) status signals.

- The system is back by a two-year warranty.

About the Author

Sean Kilcarr

Editor in Chief

Sean Kilcarr is a former longtime FleetOwner senior editor who wrote for the publication from 2000 to 2018. He served as editor-in-chief from 2017 to 2018.