Trucks, equipped with the latest technologies and features, emit tons of data for fleet managers to sort through – from fuel usage and idling to route tracking and driver behaviors. But when it comes to effectively leveraging that data to run more efficient operations, many fleets may end up feeling they fall short.

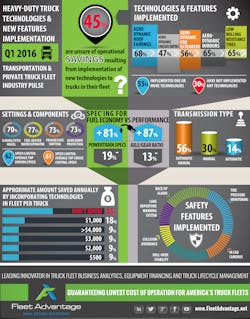

A recent Fleet Advantage survey – presented to more than 500 private and transportation fleet executives and managers – shows that 45% of respondents are unsure of operational savings resulting from the implementation of new technologies to heavy-duty trucks in their fleet.

“Ever since the recession ended, the industry has gone full-speed ahead in adopting newer technologies to their trucks that in turn provide access to a wealth of data and intelligence, especially as it relates to fuel economy,” said Mike Spence, senior vice president of fleet services at Fleet Advantage. “Unfortunately, this survey validates that data has become increasingly voluminous, and many industry professionals do not have the tools to analyze and digest this data that can then be used to make critical decisions for their fleet operations.”

Among several vehicle features designed to enhance performance and improve fuel economy, the majority of respondents (68%) said they’ve implemented the utilization of aerodynamic roof fairings. However, lack of digestible data may also be a reason why roughly a third of respondents said they’ve never used or considered features such as low-rolling resistance tires (34%), aerodynamic mirrors (34%), and aerodynamic cab extenders (34%). Also, 52% of respondents said they’ve never used aerodynamic chassis skirts.

Getting started

The first step, Spence told Fleet Owner, is identifying the information most important to your company. Then, he advises selecting a provider that could most economically provide that information in simple terms.

“Don’t try to create a situation where everything is corrected overnight,” Spence explained. “Start at what’s most important to your business in that moment. Identify those steps then you can start gathering information and see what’s available. Acknowledge how that information can help your organization and where the leaks are in your system by gathering how much information you have available. From there, the sky is the limit.”

The most important part of any fleet operation is the driver, Spence adds. So he suggests anything fleets can do to enhance driver performance will boost the company as a whole.

After the driver, he said fuel is the most important element. Spence advises that fleets utilize trucks efficiently and route them properly so all fuel expenses and usage is accounted for.

According to the survey, despite the current low cost of diesel, 81% of respondents said they spec their powertrain for fuel economy instead of performance, and 86% spec their axle/gear ratio for fuel economy as well.

“This is a positive sign as fleet executives realize that they cannot just count on diesel prices staying low for continued improvement in fuel economy and savings,” Spence said. “Today’s cutting-edge technology is designed to save more fuel than ever, but fleet executives must be able to track their fuel performance and quantify the data in order to realize the cost savings.”

In terms of safety features, the survey found most industry professionals said they’re interested in tire pressure monitors (24.2%), back-up alarms (21.0%), and roll-over stability (19.4%). Collision avoidance technologies scored the fewest responses at just 9.7%.

Spence told Fleet Owner that the purpose of the survey is to educate the industry and show private fleets that there are tools available to make them run more efficiently.

“The data is available,” Spence said. “You just need to get your organization focused on how to use the data that is most important to you. It doesn’t matter if it’s the senior VP of fleet or the local dispatcher, it is extremely important that everyone is tuned in to use the data.”

About the Author

Cristina Commendatore

Cristina Commendatore is a past FleetOwner editor-in-chief. She wrote for the publication from 2015 to 2023.